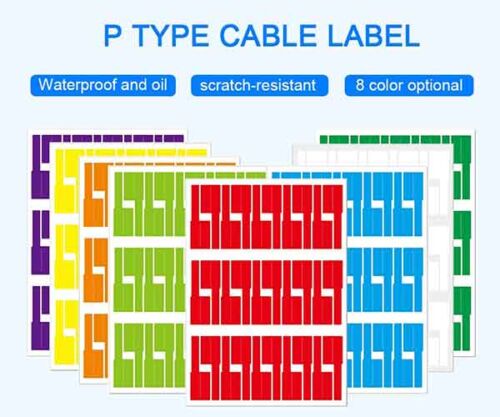

Flag Shaped Cable Labels Wire Marking

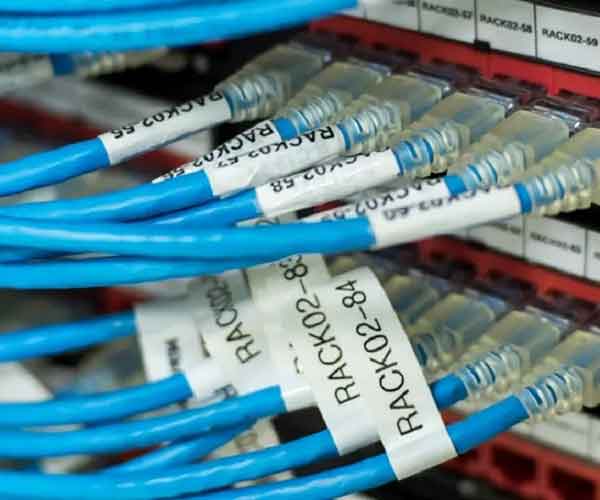

On the electronic devices, computer workstations and switch cabinets the cables must be marked correctly. This way the cables can be unambiguously assigned at a later time. The flag shaped cable labels are used for the cable marking to help technicians repair and troubleshooting. They will be placed around the cable and the ends of the label will be coinciding agglutinated and both sides for imprints with text.

Additional information

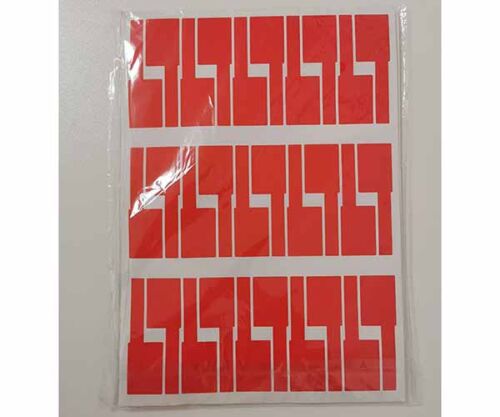

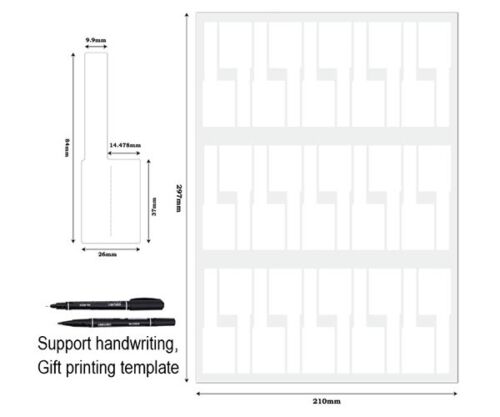

| Standard Size | 84*26mm |

|---|---|

| Standard Color | White |

| Material | Synthetic Paper |

| Suitable Printers | Thermal transfer printer |

Description

Flag shaped cable labels are so named because they are folded onto wire and the ends of the label are glued together to form a raised “flag”. This provides enough space to write information, which is useful for very thin wires. The eye-catching flag can highlight an important wire among dozens of wires.

Feature

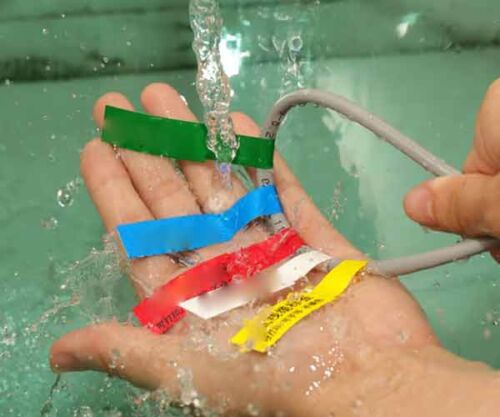

Reliable adhesion to small radii and round, low-energy and slightly oily substrates, as well as to elastomeric and structured surfaces.

Flag labels are very flexible, soft and smooth.

Due to high adhesion, the ends of the flag, which prevent sticking, will separate.

The flag labels are fully adhered to the backing, eliminating the ingress of chemicals, liquids or dirt

Also available in a larger format for easy hand application

Thermal transfer ribbons suitable for thermal transfer with high abrasion resistance

For standard compatible labels

Plain and ready-made labels in custom and special formats

Functions and Advantages

Identification labels allow you to reliably identify the cable and have the load capacity indicated on the nameplate. Information must be securely placed in a limited space. Flag shaped cable labels are very flexible in terms of materials and can be individually tailored to customer specifications. This is achieved with suitable special materials, customized die cuts and high-quality adhesives from leading manufacturers. Material selection criteria include application temperature, flammability requirements, specifications such as UL standards or specific automotive standards, and application location.

Our high-quality and precise processing using modern die-cutting technology guarantees the highest precision and reliability in the application of cable labels. As a result, even difficult-to-cut adhesive labels are handled well, improving user productivity in the long run.

Send Inquiry