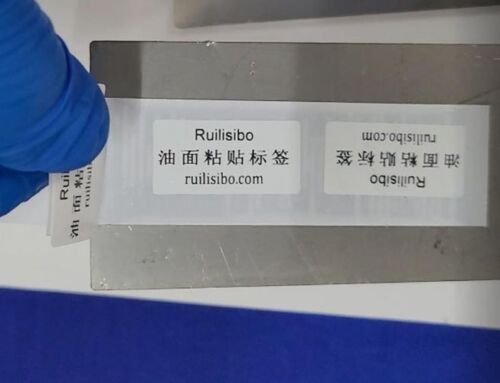

Anti-static label is a kind of self-adhesive label with anti-static permanent acrylic pressure-sensitive adhesive and white coating suitable for thermal transfer printing. It is divided into two materials: polyester and polyimide (with high temperature resistance). ESD label is designed to be marked with characters or barcodes on printed circuit boards or related electronic components that require static reduction.

High-temperature ESD labels are the ideal materials that can withstand the erosion of various fluxes and cleaning agents in the production process of various circuit boards. Ruilabels adopts anti-static adhesive and anti-static coating that are resistant to static electricity, so that only a small amount of static electricity remains on the label in a very short time. Among them, the use of self-adhesive anti-static labels greatly reduces the static electricity generated by tearing off the label from the backing paper to a safe level without damaging electronic components that are highly sensitive to static electricity. Our company has also developed an anti-static label with anti-static glue and surface material at the same time, which has super static dissipative ability, ensuring that the voltage of the label is less than 100 volts when the label is torn off in an instant, and better preventing electronic components from being damaged by static electricity.

The main purpose of using anti-static labels is that the anti-static labels greatly reduce the static electricity generated when the label is torn off from the backing paper and can reduce the static charge to a safe level in a very short time without damaging the components that are highly sensitive to static electricity.

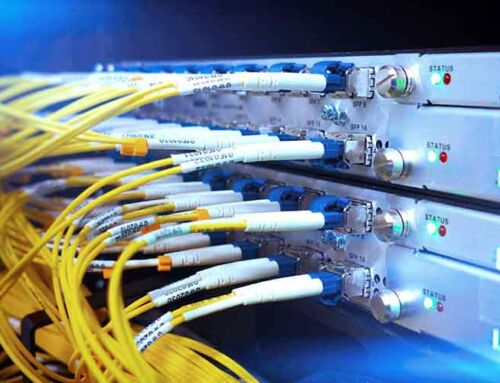

Anti-static labels protect against electrostatic damage to electronics and withstand the challenges of printed circuit board production. Static electricity can seriously damage almost any electronic component or assembly, often in a factory building but also when the product is already in use. Labels used for identification are one of the causes of static damage, regardless of whether your production staff has taken precautions such as wearing anti-static wrists, foot straps, etc. When a label is torn off the backing paper, Can generate up to 1000 volts of static electricity. Since traditionally used labels are all insulating materials, this label will retain static electricity for a period of time before recovering.

A new label material for the electronics industry that prevents electrostatic damage and withstands the challenges of printed circuit board production. Generally used for motherboards, electronic components, barcode labels, etc.

Ruilabels provide made-to-order labeling solutions to address your unique labeling needs. Please feel free to contact us if you have requirments on labels.