Why do tires need to be vulcanized?

The internal microstructure of the rubber used in the production of tires is linear polymers before vulcanization. It is a plastic rubber with viscoelasticity. It is easy to deform, has low strength, and has no use value; through vulcanization, the linear polymers in the plastic rubber are cross-linked. The reaction generates a network-like polymer material, which turns into a valuable and highly elastic rubber, which appears as solidified macroscopically.

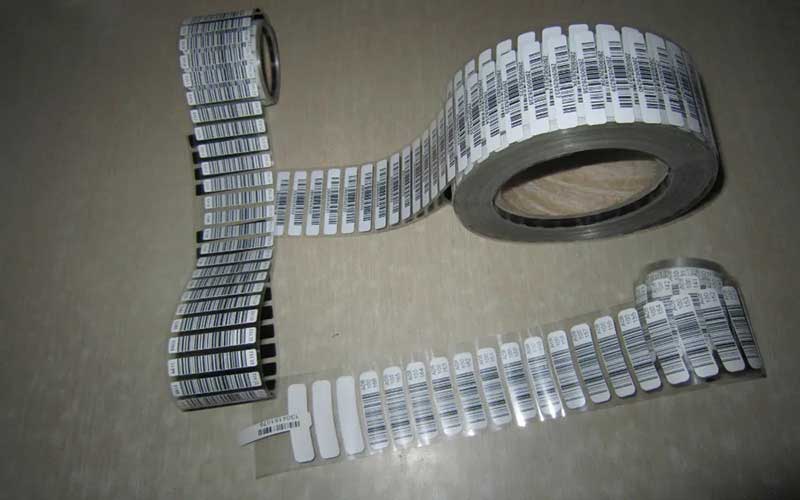

Tire vulcanization labels are designed for the application of tire vulcanization processes. The vulcanization temperature can reach 210°C, and the short-term vulcanization temperature is even higher. The vulcanization label can be vulcanized simultaneously with the tire. After vulcanization, the barcode on the label is integrated with the tire and will never fall off, and can accompany the entire life cycle of the tire.

The role of a vulcanized barcode labels

The vulcanization label was born in the late 1980s. By the late 1990s, it had played a very significant role in the tire production process, quality inspection, quality tracking and production cost control.

Tire vulcanized barcode labels have excellent thermal transfer performance and long-term readability, and provide visibility and traceability throughout the supply chain. Therefore, many tire manufacturers have used vulcanized labels on tires.

Performance requirements for tire vulcanization barcode labels

(1) Can withstand the heat and pressure of tires during high temperature and vulcanization treatments.

(2) Provide durability and anti-wear properties.

(3) Integrated into the adhesive system, it can form a strong permanent bond when tires are processed at high temperatures and vulcanized.

(4) Able to achieve 100% accurate first reading scan on a high-speed transmission pipeline.

(5)Each barcode is a sequence code of different data

Application of tire vulcanization barcode labels

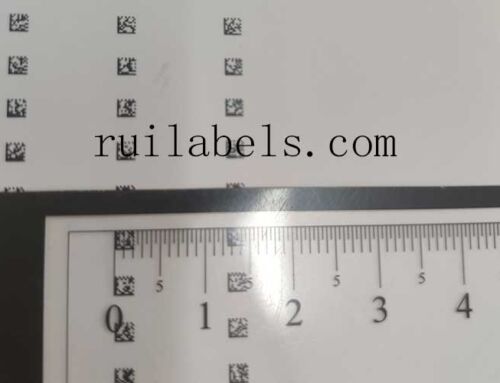

In recent years, with the popularization of mobile terminals such as smartphones and the rise of QR code applications, tire manufacturing companies are studying the management of one-dimensional barcodes on vulcanization labels and QR codes on tread labels, so that users can Understand more manufacturing information of tires more intuitively

Ruilabels provides high performance labeling solutions, for more information about labelling solutions for your applications, please feel free to contact us.