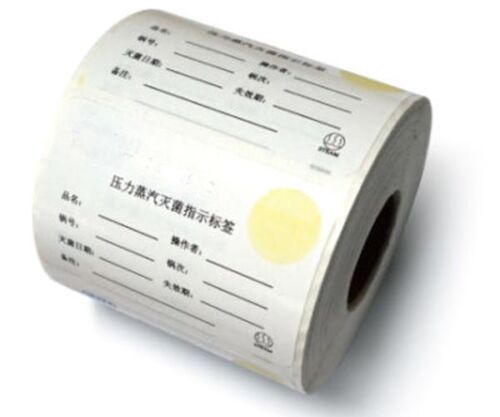

Autoclave Chemical Indicator Labels

Autoclave Chemical Indicator Labels are specially used to paste outside the package to be sterilized, used to mark whether the package has been autoclaved steam sterilization process, to prevent mixing with the package of unsterilized items.

Additional information

| Size | Custom |

|---|---|

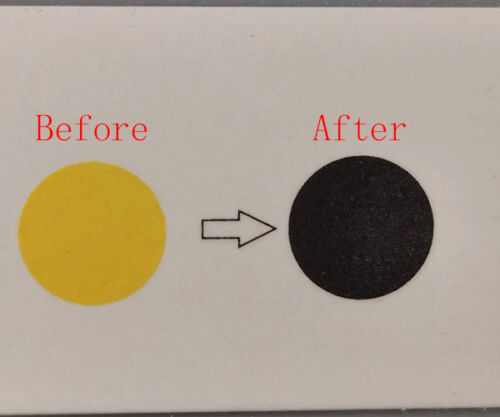

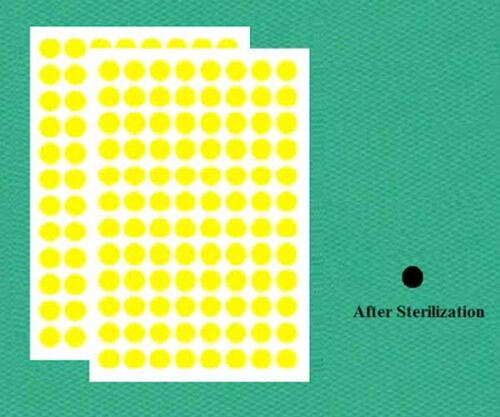

| Color | From Yellow to Black |

| Material | Special Paper |

Description

Autoclave Chemical Indicator Labels

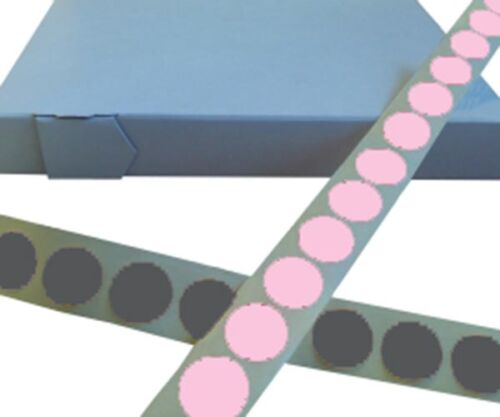

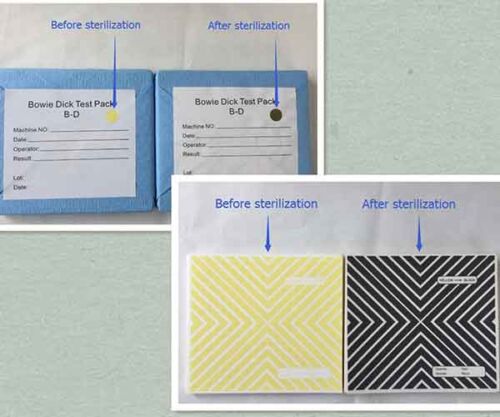

Autoclave Chemical Indicator Labels are made of paper as the base material, and the chemical substances, coloring agents and auxiliary materials are made into ink and printed on special cardboard, which shows that the color of the indicator color block changes from yellow to black under the appropriate temperature, humidity and pressure, so as to quickly and intuitively reflect whether the sterilized goods have been sterilized, and the color is not easy to fade after sterilization.

Autoclave sterilization label is specially used to paste outside the package to be sterilized, used to mark whether the package has been autoclaved steam sterilization process, to prevent mixing with the package of unsterilized items.

Usage

Autoclave sterilization labels are widely used in hospitals, pharmaceutical, food, health care products, beverage and other industries sterilization effect detection.

Instruction for use

1. Place the sterilization indicator label in the center of the standard test package or item

2. According to the routine of sterilization operation, when the saturated steam is sterilized at 121 (+-2)°C, the indicator label turns from yellow to black, and the sterilized package can be judged to have been sterilized; if the color of the indicator label changes unevenly or the color does not change, it indicates that the package has not been sterilized.

3. Under the steam condition of 121℃, the action is 15 minutes, and the indicator label changes from yellow to black. Under the steam condition of 132℃, the label will change from yellow to black after 3.5 minutes.

Note:

Do not place the packets close to the interior wall of the cabinet, and do not attach the labels directly to hard surfaces such as metal or glass where condensate is easily formed, or place them inside infusion bottles, tubes, barrels and other instruments to avoid causing the packets to become wet, so that the condensate will wet the chemical indicator cards and the heat-sensitive material of the indicator will lose its accuracy.

Saturated steam pressure should be ≥ 0.3Mpa, the transport of saturated steam pressure is not enough, or due to a small amount of leakage to reduce the saturated steam pressure, the vacuum is reduced, but the discharge of cold air can not meet the requirements.

When using pipeline to send gas, the distance of exposed steam pipeline will produce condensate, which will increase the water content of saturated steam and affect the sterilization effect.

Do not use containers with covers such as porcelain jars and glass jars for sterilization treatment, so as not to affect the entry of saturated steam and the entry and exit of cold air and make sterilization fail.

Low temperature in the cabinet or insufficient action time will lead to sterilization failure.

This product should be stored at room temperature 15°C~30°C, 50% relative humidity, do not get wet.

Avoid light (including sunlight, fluorescent light and ultraviolet light) and humidity, do not get wet.

The product should not be exposed to corrosive gases such as acids and bases, and should not be co-located with contaminated or toxic chemicals to avoid affecting the color rendering performance of the indicator.

If you find that the indication mark of the product appears to be discolored, do not use it.

The used indicator label, its discolored reagent part, should not be burned by fire to prevent the generation of dust.

Send Inquiry