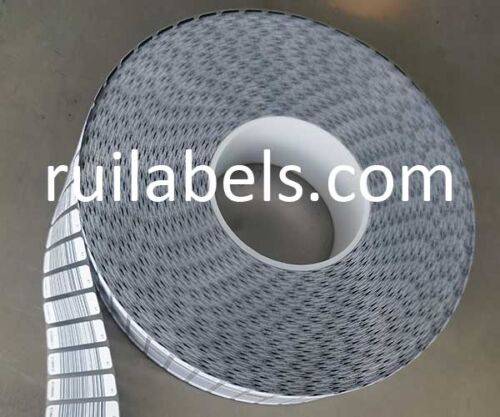

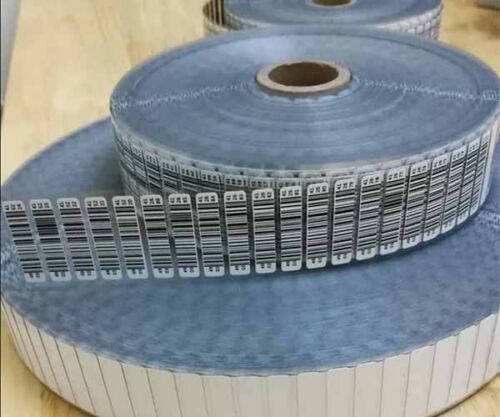

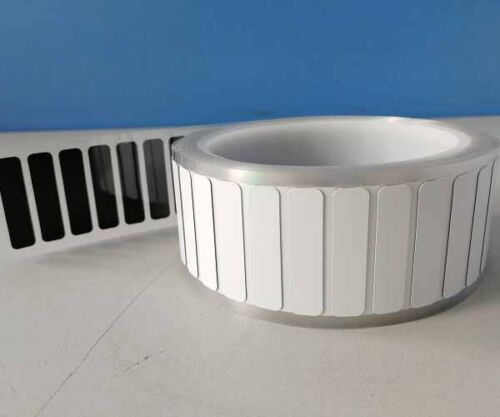

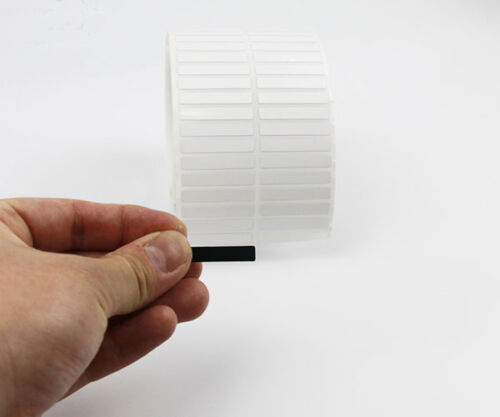

Barcode Vulcanization Label for Tires Manufacturing

The vulcanization (or curing) process in tire manufacturing is a challenge for these labels. Heat (up to 200°C) and high pressure can easily damage a label. It is important to note that whether you add a tire label during calendaring or before curing, both will be subject to heat and pressure. Due to vulcanization and the rigors of tire manufacturing, it is important to choose durable label materials that withstand extreme heat, preventing smudging of barcodes and oozing of adhesives. Ruilabels barcode vulcanization label give you the best durability option.

Additional information

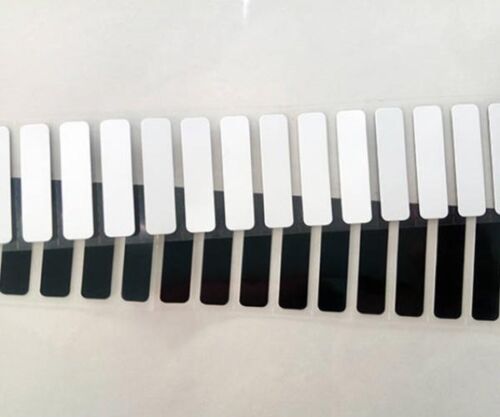

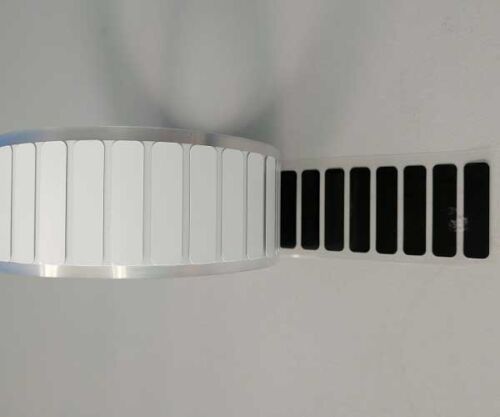

| Size | 30*12mm |

|---|---|

| Material | Polyester |

| Print Technology | Pre Printed, Thermal Tranfer Printing |

Description

Barcode Vulcanization Label for Tires Manufacturing

If a tire bead label is placed on a raw tire, it is also called a vulcanization label and therefore must withstand the vulcanization process. The vulcanization (or curing) process in tire production poses a challenge for these labels. Labels are easily damaged by heat (up to 200°C) and high pressure. It is important to note that whether tire markings are added during calendering or before vulcanization, both factors are affected by temperature and pressure. Due to the stringent requirements of vulcanization and tire manufacturing, it is important to select a durable label material that can withstand extreme temperatures and prevent barcode smudging and adhesive bleeding. Thermal transfer labels provide maximum durability.

Labels are typically designed to be adhered to the surface of the material, while tire bead (or vulcanized) labels can be embedded directly into the tire. This provides additional security and allows manufacturers to scan barcode labels to determine if their tires are safe and ready for sale. If the tire is considered ready for sale, the tread will be labeled with a more attractive label and sent to the retail supplier.

Send Inquiry