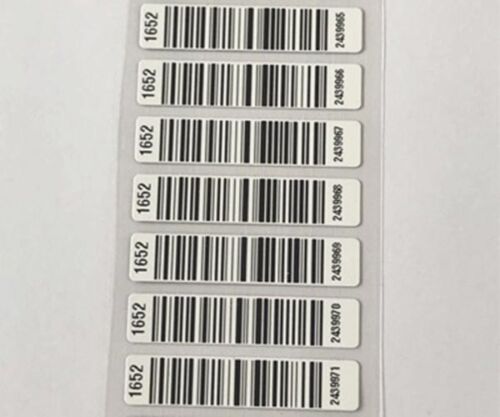

BC Labels for Green Tire Curing/Vulcanization

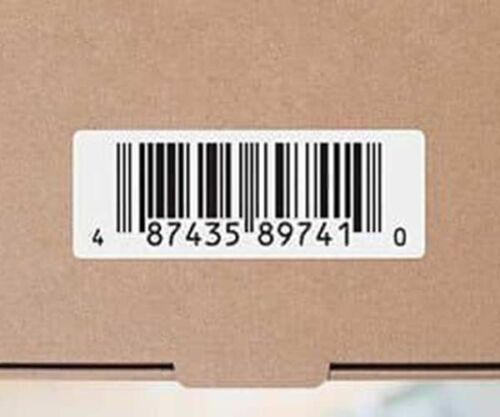

The BC labels are designed for the tire vulcanization process management during the tire manufacturing process. The label is affixed to its sidewall before vulcanization to help people track raw materials and process details throughout the supply chain. This BC label is applied to the unvulcanized “green tire” and is integrated with the tire during the vulcanization process. BC labels maintain excellent tack and readability throughout the life of the tire.

Additional information

| Size | 41*10mm, customized |

|---|---|

| Color | White |

Description

BC Labels for Green Tire Curing/Vulcanization

Features: waterproof, acid-resistant, alkali-resistant, salt-resistant, resistant to most petroleum oil stains, and low-fat solvents, wear-resistant, high and low temperature resistant, no deformation, no discoloration, suitable for most resin ribbons

- Excellent barcode/thermal transfer printing effect

- Exhibits excellent adhesion to tires before and after curing

- Can withstand the pressure and temperature of the vulcanization process (up to 200°C)

Applications: suitable for tire tread marking, vulcanization process management in tire production, quality traceability labels, permanent identification labels for rubber products such as industrial belts, tire and vehicle management in tire factories and automobile factories.

The vulcanization process is an important part of the tire manufacturing process. At this time, the unvulcanized “tire green embryo” will be placed in a vulcanizer for hot-pressing treatment, so as to be vulcanized to form a finished tire with patterns or text and tread patterns. Ruilabels BC Labels are exceptionally resistant to abrasion and heat, and their excellent readability allows you to track tires throughout the supply chain.

Send Inquiry