High-Temperature-Resistant Label For Reflow Process

High-Temperature-Resistant Label is made of polyimide film as a base material and coated with a unique pressure-sensitive adhesive. It has good chemical resistance and abrasion resistance. It keeps the product in high temperature environment without warping, peeling and discoloration for a period of time, and the information on the label surface is clear.

Additional information

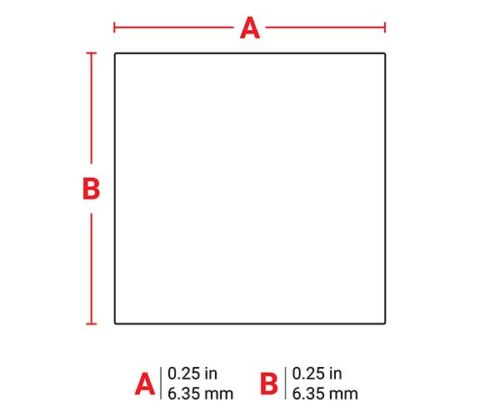

| Size | Custom |

|---|---|

| Color | White |

| Material | Polyimide |

| Print Technology | Thermal transfer |

Description

High-Temperature-Resistant Label For Reflow Process

As a self-adhesive product used in highly demanding high-temperature production environments, high temperature labels need to keep the product from warping, peeling and discoloring over a period of time in high-temperature environments to ensure clear information on the label surface. Therefore, there are strict requirements for the base material layer, surface coating and adhesive backing layer of the label.

Usually, high temperature labels are made of polyimide film as the substrate and coated with a unique pressure-sensitive adhesive. It has good chemical resistance and abrasion resistance. It has specific corrosion resistance to fluxes, melting agents, cleaning agents and other chemicals. It maintains excellent performance when used in extremely harsh environments with high temperatures and abrasion.

Application Scenarios

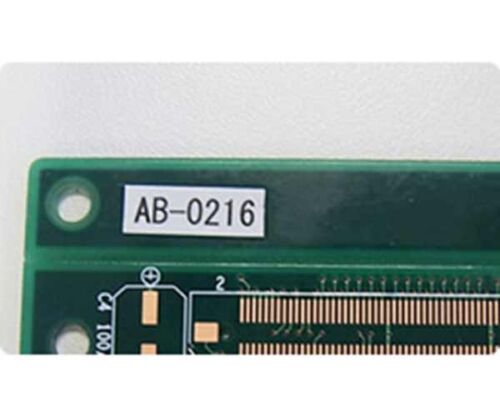

Motherboard labels In the electronics industry, it is specifically designed for character or barcode labels for printed circuit boards

High-temperature-resistant label is designed because it can withstand the solder and melting agent when producing printed circuit boards. The current thicknesses are mainly 25um and 50um. the standard colors are black and white. High temperature labels are widely used in SMT and wave manufacturing of many electronic products, high temperature resistant labels for motherboards, corrosive products, cell phones and lithium batteries. Astatec GW003 motherboard labels are widely used in the electronics industry and perfectly meet the requirements of high temperature resistance and solder corrosion resistance.

Advantage

1. It has electrical insulation;

2. It has meager stripping force, and die-cutting can be marked automatically;

3. The cost is objectively, and the waste can be discharged automatically

4. High and low-temperature resistance – 40 ℃ – 350 ℃;

5. Bar code printing is clear;

6. Excellent characteristics: waterproof, wear-resistance, and scratch resistance;

7. Excellent development characteristics: chemical corrosion resistance, pollution resistance, chemical reaction solvent resistance, tensile resistance, and tear resistance;

Specifications

| Name | High-Temperature-Resistant Label For Reflow Process |

|---|---|

| Material | Polyimide |

| Adhesive | High temperature adhesive |

| QR code and serial number or other custom printing content | |

| Application | Circuit Board Labeling, Component and Equipment Labeling |

| Service Temperature | Resistant to high temperature up to 350℃ |

| Shelf Life | Stored at 26° C / 60% relative humidity for 1 year |

| Quantity per row | 4 |

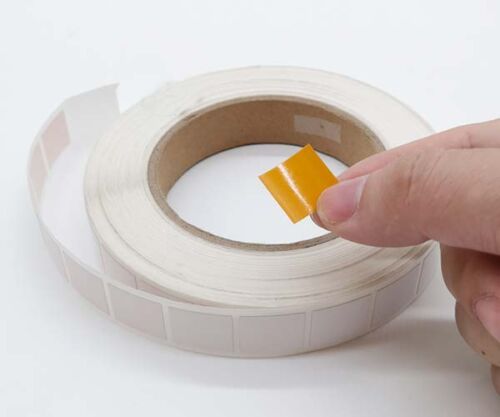

| Label Format | In Roll |

| Labels per Row | 10000 |

| Suitable Printers | Thermal Transfer printers |

| Sample | Free sample available if in stock |

| Payment Term | T/T, L/C, Paypal, Western Union… |

| Production Time | 5-7 working days after drawing confirmed |

Send Inquiry