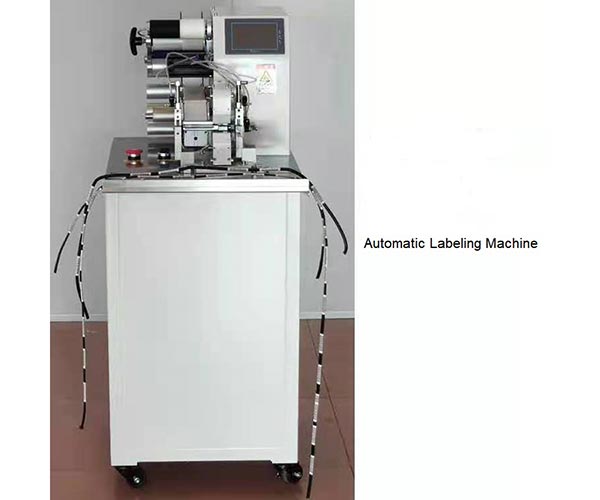

Label Winding Machine Automatic Wire Labeling

The Label Winding Machine is suitable for automatic labeling of round wires, double-spliced and multi-spliced wires, flat wires, stranded wires, and loose wires sharing one machine for automatic labeling, wire and cable labeling (barcode labels, warning labels, instruction labels, etc.), Just put the wire and cable at the label, you can automatically label the label without manual support

Additional information

| Applicable Cable Dimensions | Width 5~45(mm) Length 20~100(mm) |

|---|---|

| Weight | 40kg |

| Machine size | 680×600×980(mm) |

Description

Label Winding Machine Automatic Wire Labeling

Functions of the Wire Labeling Machine:

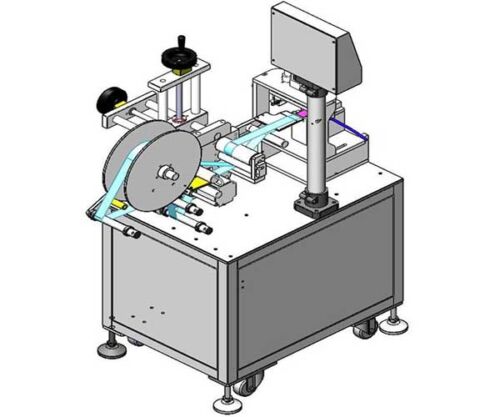

1: The labeling machine is suitable for round wire, double and multi-joint wire, flat wire, stranded wire, loose wire sharing a machine for automatic labeling, wire and cable label pasting (barcode label, warning label, instruction label, etc. ). You just put the wire and cable on the label, and don’t need to manually hold the line, and you can automatically labeling when you step on the pedal machine.

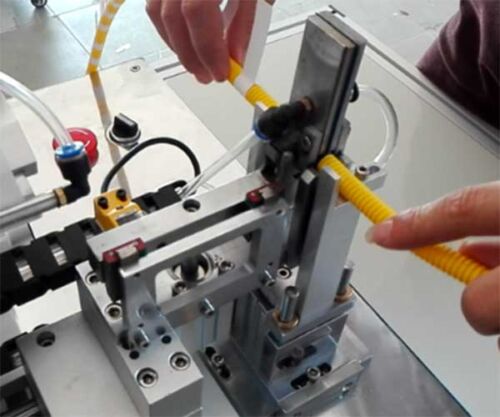

2: Round wire, flat wire, plugs at both ends, etc. can be used (the wire does not need to be rotated, and it will not hurt the inner wire of the wire). This not only changes the traditional manual labeling method, improves the efficiency of labeling, and improves the disadvantages of uneven size and wrinkles that are prone to occur in manual labeling, but also saves labors. Improve production efficiency, solve the advantages of slow manual labeling, insufficient accuracy, personnel changes and high labor costs.

3: Optional printing function, real-time printing, online printing, printing and posting one, printing and labeling in one step.

Features of Wire Labeling Machine:

It is mainly a labeling equipment that sticks the 360-degree roll of self-adhesive labels on the wire body. It is an intelligent automation equipment newly developed for the wire and cable processing industry. It is mainly used for bar code labels, warning labels, instruction labels and other rolls to be attached to wires, such as notebook power cords, desktop computer plug wires, printer plug wires, digital camera charging cables, video camera power cables, etc. Greatly improve production efficiency, reduce costs, and bring benefits to the majority of enterprises.

Advantages of Wire Labeling Machine:

Labeling principle of the labeling machine: The line does not move, the label rotates, and the line is not damaged. The long line, the flat line, the double-stitched line, and the scattered line can be automatically labeled, and the change of the line diameter can be easily solved by adjusting the number of labeling rolls.

Wire labeling machine is a special type of equipment for labeling wires and plug power cords. It is an intelligent automation equipment newly developed for the wire, plug power cord processing industry.

It is mainly used for bar code labels, warning labels, instruction labels and other rolls to be attached to wires, notebooks, desktop computers, printers, digital cameras, video cameras, PDAs, mobile phones, etc. Power lines, data lines, DC power lines, etc. can be seen here. There are various types of roll-on labels, of which barcode labels are the most common. In China’s manufacturing industry, especially in the wire and plug power cord industry, nearly 80% of the plug power cords, data cables, and power supply lines used in the world are made and processed in China, and the prospects are very promising.

Techical Info

| Item | Label Winding Machine Automatic Wire Labeling |

|---|---|

| Applicable Product Range | 1.6mm~15mm round wire, flat wire scattered wire |

| ApplicableLabel Range | idth 5~45(mm) length 20~100(mm) out of range customization |

| Labeling Accuracy | ±0.2mm |

| Labeling Speed | 1500PCS/hour (depending on label size and manual operation speed) |

| Power Supply | Single-phase AC 220V 50HZ 120W |

| Ambient Temperature | +5~+40℃ |

| Relative Humidity | (20~90)%RH |

| Access Gas Source | 0.4 MPa (4Kgf/cm 2) |

| Whole Weight | 40kg |

| Dimensions | 680×600×980(mm) |

Send Inquiry