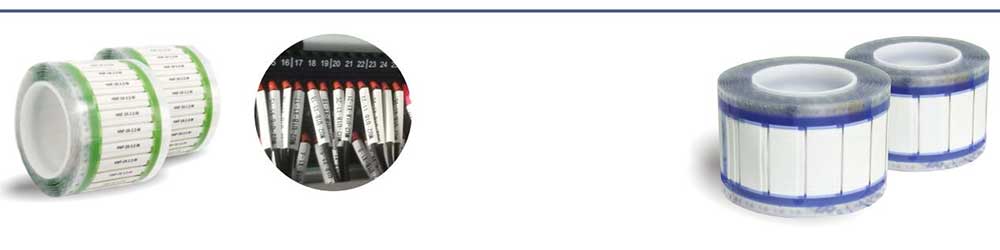

Military Grade Polyolefin Heat Shrink Labels

These heat shrink labels are designed to meet the high surface requirements of wire and cable marking, it is made of radiation cross-linked polyolefin. The product can be permanently marked after direct printing and retains good character recognition even when exposed to aggressive cleaning agents, military fuel.

Additional information

| Size | Accept custom |

|---|---|

| Color | White, Yellow or custom colors |

| Material | Polyolefin |

| Print Technology | Thermal transfer |

Description

Military Grade Polyolefin Heat Shrink Labels

Flexible, highly flame-retardant.

Corrosion No corrosion

Fluid resistance: (23℃, 24 hrs) Followed by print performance tests of SAE-AS81531

Markers can also provide insulation and strain relief.

Marks are permanent after printing; mark performance improves after shrinking.

Free of PCBs, PCPs, polybrominated biphenyls (PBBs), polybrominated biphenyl oxides and ethers (PBBOs, PBBEs and PBDEs) and toxic heavy metal compounds, which are classified as environmentally hazardous substances. Conform to European RoHS environmental directive..

Specification

| Item | Military Grade Polyolefin Heat Shrink Labels |

|---|---|

| Type | Insulation Sleeving |

| Material | Polyolefin |

| Material Property | Highly flexible, light weight, flame retardant |

| Operating Temperature Range | –55°C~+135°C |

| Shrink Ratio | 2:1/3:1 |

| Min.Shrink Temperature | 85°C |

| Min.Full Recovery Temperature | 135°C |

| Suitable Printers | Barcode thermal transfer printers |

| Printing | Single-sided printable/Double-sided printable |

| Payment Term | T/T, L/C, Paypal, Western Union… |

| Lead Time | 7-10 working days |

Heat shrink labels (Heat Shrink Sleeves) are designed to meet the requirements of high- performance identification of wire and cable, tools, hoses and equipment. Made from reliable flame-retardant polyolefin with outstanding properties, sleeves can also be used as electrical insulation. Marks are permanent after printing.

Physical properties:

Tensile strength 10.4MPa min.

Elongation 200% min.

Low temperature flexibility No cracking

Heat shock No cracking, dripping or flowing

Print performance:

UL224 50 rubs, legible

MIL-M-81531 50 rubs, legible

MIL-STD-202 30 strokes, legible

Electrical properties:

Dielectric voltage withstand 2.5kV, 60 sec No breakdown

Dielectric strength 19.7kV/mm min.

Volume resistivity 1014Ω·cm min.

Chemical properties:

Corrosion No corrosion

Flammability Average burn time is less than 1 minute

Fluid resistance: (23℃, 24 hrs) Followed by print performance tests of SAE-AS81531

Product Parameters

| Properties | Index | Test Method |

|---|---|---|

| Tensile Strength | ≥10.3 MPa | ISO 37 |

| Breaking Elongation | ≥200% | ISO 37 |

| Tensile Strength after Aging | ≥6.9 MPa | ISO 188(175℃×168h) |

| Breaking Elongation after Aging | ≥100% | ISO 188(175℃×168h) |

| Axial Rate of Change | 2X:-10%~+1%,3X:-15%~+5% | UL224(200℃×3 min) |

| Flame Retardancy | VW-1 | UL224 |

| Thermal Shock | without cracks, no dripping | UL224(250℃×4h) |

| Cold Formed Flexible | without cracks | UL224(-55℃×1h) |

| Water Absorption | <0.5% | ASTM D 570 |

| Breakdown Strength | ≥19.7 MV/m | IEC 60243 |

| Volume Resistivity | ≥1014 Ω·cm | IEC 60093 |

Send Inquiry