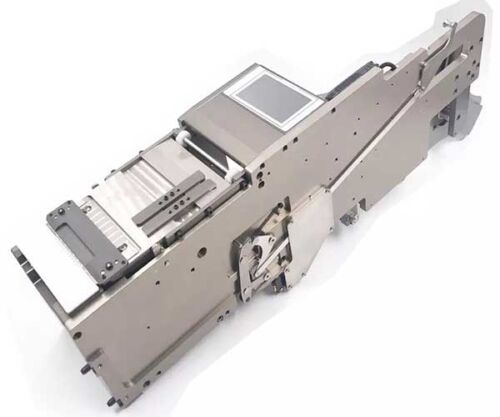

NXT Label Feeder

NXT Label Feeder is designed with solid aluminum alloy, it is lightweight, strong and durable. Support single-column and multi-column simultaneous output. There is no need to purchase a labeling machine separately, the placement machine can be combined with the label feeder to realize the attachment of barcode labels.

Additional information

| Size | 670.5*286mm |

|---|---|

| Weight | 3.5Kg |

| Positioning Accuracy | ±0.2mm |

Description

NXT Label Feeder

Designed with solid aluminum alloy, it is lightweight, strong and durable.

Advanced forward push feeding, first stripping and then absorbing.

Support single-column and multi-column simultaneous output.

±0.3mm feeding accuracy and >99.7% output rate.

32-bit high-efficiency processor is adopted, reflecting excellent control performance.

The closed-loop control structure can dynamically adjust the output torque in real time while preventing lost steps, and the output is more stable.

Excellent usability, supports online mode and automatic mode.

There is no need to purchase a labeling machine separately, the placement machine can be combined with the label feeder to realize the attachment of barcode labels.

Strong compatibility of material types: Whether it is paper labels, FPC reinforced steel sheets, various Mylar tapes, foam, dust-proof nets, high-temperature tapes, etc., the label feeder can be used for roll materials.

Strong material size compatibility: a label feeder can realize all sizes of materials within the maximum size, and supports single or multiple

Touch Screen

The high-definition touch screen displays all feeder production information, which is concise, intuitive and generous.

Commonly used function buttons are distributed on the home page, and more function expansion settings are displayed in the background to meet different production needs.

The touch screen setting includes hierarchical management authority, which can prevent the modification of setting parameters caused by accidental touch to the greatest extent.

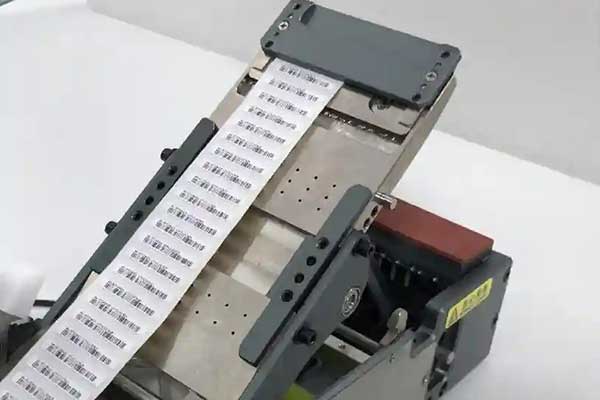

Clamshell Design

The clamshell design of the stripper plate allows for the fastest material change.

Vacuum hole adsorption can stabilize the tension of the tape and facilitate the successful peeling of viscous materials.

The sliding sidewall allows one feeder to meet the use of more width size materials.

The height gap can be adjusted by the set screws around the magnetic pressing cover to meet the smooth passage of materials with different thicknesses.

Fiber Pick and Place Platform

The surface of the thin-hole optical fiber receiving platform is smoother than that of the strip groove receiving platform.

The anti-stick silicone pad ensures that the adhesive tape or foam can be easily absorbed, and the replacement is easy and the maintenance cost is low.

The high-sensitivity optical fiber sensor can meet the needs of single-row to multi-row (up to 12 rows) labels with different gaps to be stripped at the same time.

The design of the up and down lifting slide table can easily and accurately set the height of the reclaiming platform, which is suitable for the successful peeling of materials of different thicknesses.

Super Wear-resistant Rubber Wheel

The feeding method of rubber-covered wheels and gears solves the problem of feeding errors caused by slippage of the bottom paper.

The bevel-cut locking design and the increased contact area between the backing paper and the gears facilitate opening and ensure safe and effective locking.

Mechanical Tension Axis

The standard configuration is an inner diameter of 76.2mm (3 inches) and an outer diameter of 220mm for material hanging mechanical tensioning shaft, which is convenient for loading and unloading and effectively clamps.

The optional tension shaft assembly with an inner diameter of 152mm (6 inches) can meet the requirements of multi-size inner diameter roll labels.

Optional discharge box structure is available.

Precision Advantage

The advanced and flexible stripping platform supports adjustable width for different strips.

In the design of the fixed material belt, the method of pressure is abandoned, and the design of adsorption is adopted to ensure the original state of the material to the greatest extent.

The reclaiming platform with excellent anti-sticking effect minimizes the adhesion of the material when the label is released, avoids material deformation and improves the position accuracy of the discharge.

Specification

| Item | NXT Label Feeder |

|---|---|

| Feeding Method | Peel first and absorb later |

| Liner Width | 10mm~30mm |

| Liner Thickness | ≤0.1mm |

| Linner Material | PET |

| Label Width | ≥3mm, ≤liner width |

| Label Thickness | ≤1mm |

| Reel Core | 3inch |

| Positioning Method | Optical fiber + software |

| Position Accuracy | ±0.2mm |

| Input Power | DC24.0V|1.5.0A MAX |

| Drive Mode | Electric |

| Operating Temperature/Humidity | Working temperature: -20~65℃ Working humidity: 20~90%RH |

| Shelf Life | >= 20K hrs.(25°C) |

Send Inquiry