Surgical Instrument Marking Label Stickers

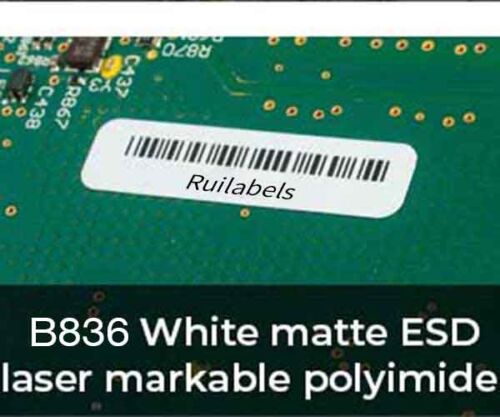

Ruilabels offers small, laser-engraved Datamatrix barcode labels that can be applied directly to an instrument’s surface. These dot labels re an effective and affordable solution for tracking individual surgical instruments and can be incorporated into most existing instrument tracking software.

Additional information

| Size | 3*3mm, 5*5mm, 6*6mm, 7*7mm… |

|---|---|

| Color | White Barcode on Black Label |

| Material | Paper, Synthetic paper,PE,PET,BOPP,etc |

| Print Technology | Thermal Transfer |

Description

Surgical Instrument Marking Label Stickers

Ruilabels offers dot labels that are an effective and affordable solution for tracking individual surgical instruments and can be incorporated into most existing instrument tracking software.

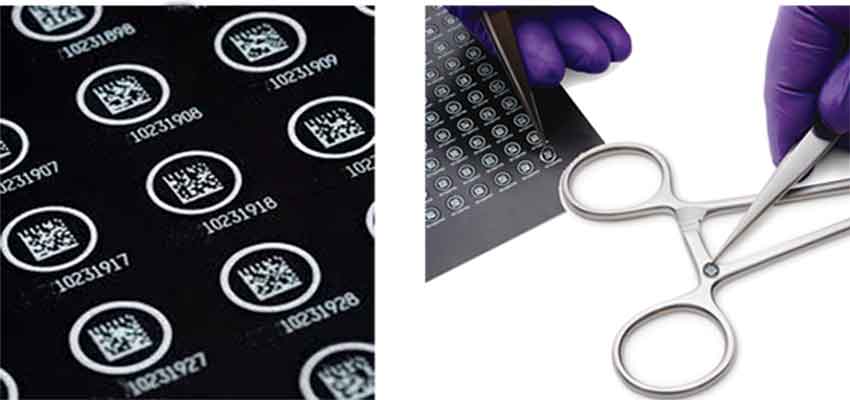

These labels are small, laser-engraved Datamatrix barcode labels that can be applied directly to an instrument’s surface. Each barcode contains a unique number or a hospital’s GS1 code, allowing them to be tracked individually throughout the whole sterilisation, usage and cleaning cycles. Dot labels are available in a number of sizes, starting from just 3mm in diameter.

Designed to withstand harsh environments and temperature conditions, dot labels can last up to 200 processing cycles and have been scientifically evaluated for sterility and biocompatibility by an independent medical testing laboratory who have established that dot labels are safe for use on surgical instruments

How are dot labels applied?

The application of dot labels is quick and easy. Simply clean the application thoroughly to ensure it is free from any grease or contaminants, lift the required dot label from its sheet with tweezers and apply to the selected area on your instrument. Then, apply a firm pressure to ensure 100% contact between the key dot and your instrument, before sterilising the instrument, which will help ‘wet-out’ the adhesive to form a strong bond.

How do dot labels work?

The barcode links a specific instrument to a data file within the hospital’s software application, so that a particular instrument can be tracked through the entire instrument processing cycle.

Instruments with a key dot identifier are scanned using a 2D barcode reader.

Send Inquiry