-

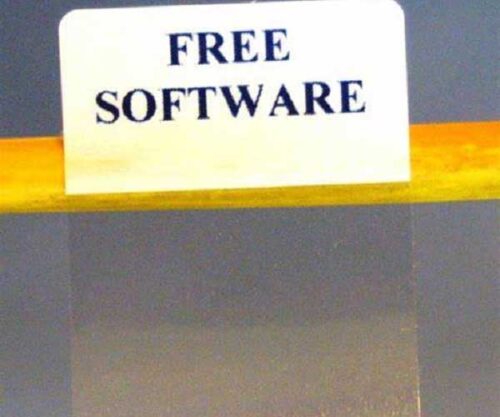

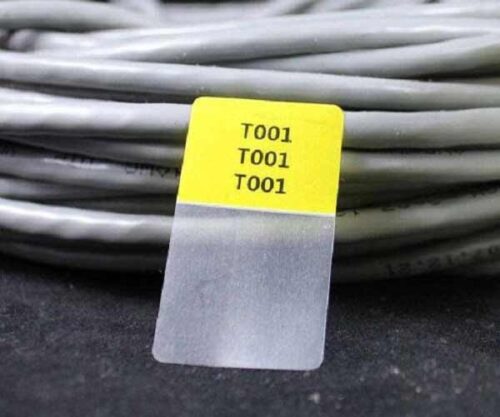

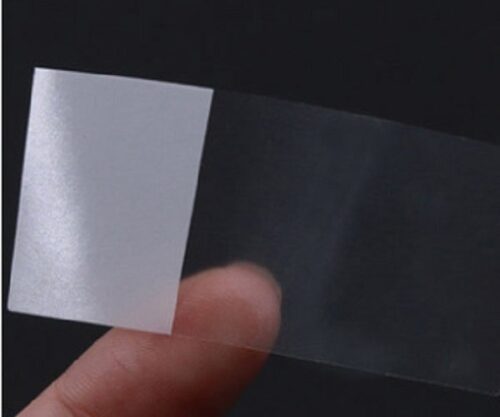

Wire Labels consist of printable or writeable area and clear laminating area. The clear laminating ensures that the printed text is resistant to moisture, smudges and mechanical wear. Due to their flexibility, most of these cable labels are also suitable for flat ribbon cables, some of which meet high temperature and outdoor requirements.

Wire Labels consist of printable or writeable area and clear laminating area. The clear laminating ensures that the printed text is resistant to moisture, smudges and mechanical wear. Due to their flexibility, most of these cable labels are also suitable for flat ribbon cables, some of which meet high temperature and outdoor requirements. -

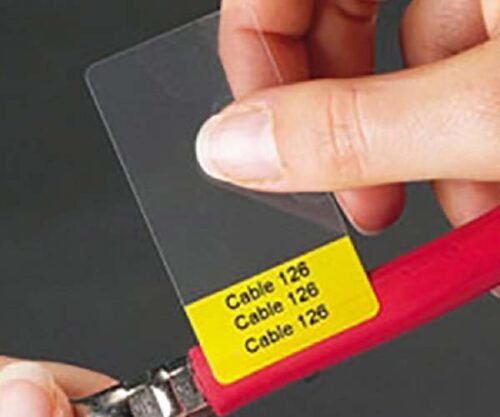

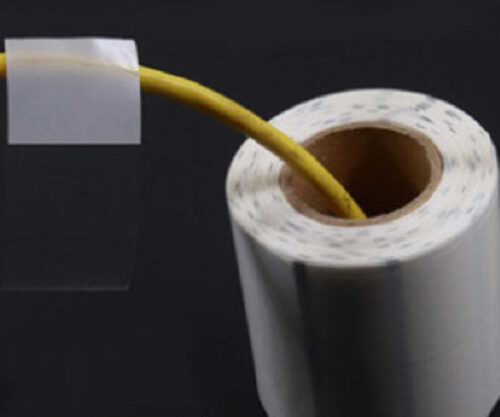

The structure of the label ensures that once the label is applied to the wire it remains in place without lifting. The information is printed onto the white inscription area. The printed information area is placed onto the wire and the transparent tail is wrapped around the wire and covers the text; this gives excellent protection from abrasion, dust and debris.

The structure of the label ensures that once the label is applied to the wire it remains in place without lifting. The information is printed onto the white inscription area. The printed information area is placed onto the wire and the transparent tail is wrapped around the wire and covers the text; this gives excellent protection from abrasion, dust and debris. -

These labels can be used for equipment room wiring, network engineering, cable engineering, electrical control cabinet cables and telephone lines, etc. It is an identification mark used in on-site installation and post-maintenance. The use of cable labels can ensure the orderliness and correctness of installation, and the convenience of post-maintenance and inspection.

These labels can be used for equipment room wiring, network engineering, cable engineering, electrical control cabinet cables and telephone lines, etc. It is an identification mark used in on-site installation and post-maintenance. The use of cable labels can ensure the orderliness and correctness of installation, and the convenience of post-maintenance and inspection. -

Wrap wire labels are manufactured from high quality clear polyester film coated with a permanent, pressure sensitive, UV resistant adhesive. They are even approved for indoor and outdoor use with occasional exposure to oil and water. Laser-printed cable labels can also be repurposed for medical applications and laboratory equipment.

Wrap wire labels are manufactured from high quality clear polyester film coated with a permanent, pressure sensitive, UV resistant adhesive. They are even approved for indoor and outdoor use with occasional exposure to oil and water. Laser-printed cable labels can also be repurposed for medical applications and laboratory equipment.