When labeling printed circuit board (PCB) and components, you need a label that will perform under some of the most extreme processing and use environments.

The label itself and the printed or barcoded information must survive high heat, exposure to chemicals, washes, and abrasion. Special material labels, such as antistatic, reduce/eliminate the damage from volts of static charge when the label is peeled from its liner.

Ruilabels offers high-performance labelling solutions that can help customers conquer ever-changing printed circuit boards by offering labelling solutions that maintain label integrity in today’s more challenging PCBA environments.

- Polyimide label material

- Ideal for marking and traceability of circuit board and electronic components

- Extremely high temperature resistance, short-term heat resistance up to 350°C

- Able to withstand harsh circuit board manufacturing environments

- Resistant to most cleaning solvents and chemicals

- Can be thermal transfer printed

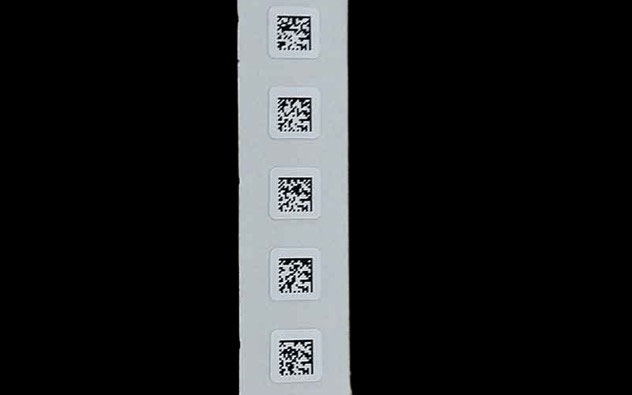

- The size of the label is 5 X 5 mm, the QR code/Datamatrix and serial number can be printed on the surface of the label

Maintaining the adhesion, durability and readability of the labels during the production process is key to an efficient PCBA process. This is why Ruilabels continues to refine its high-temperature and chemical resistant labels. Starting with a polyimide (PI) face layer, Ruilabels PCB labels have a top coat optimised for heat resistance, chemical resistance and scratch resistance for fixing to the PCB, chemical resistance and scratch resistance for fixing bar code text and for protecting the label from extreme chemicals, aggressive solvents and degradation.

Ruilabels provides not only wet surfaces labeling solution, for more information about labelling solutions, please feel free to contact us.