–Resists weathering caused by the outdoors, durable labels create peace of mind.

Ruilabels is committed to innovating the production of durable, reassuring and economical outdoor tags, bringing stronger, better quality and more durable products to the market.

Manufacturer must continue to push the durability of outdoor products to the limit in order to keep up with industry trends, as the increasing popularity of outdoor equipment.

Because products are designed to last longer, the labels on the products must also have a longer life.

Outdoor labels must remain firmly attached to the product for the life of the product, and product information such as batch number, barcode, safety warnings, and warranty must be clearly visible on the label. If labels are prone to peeling off, losing color, illegibility, scratches, or fading due to the environment, important information will be lost.

Tofind outdoor labels that are durable, reassuring, and cost-effective starts with understanding how durable labels for outdoor products are tested and how to select them. Let us take you through some things to note about labels.

Different application conditions require tags to have different specific properties. Choosing the right material for the part to be labeled requires understanding the intended use. Among the many variables, the following points need to be considered:

> The substrate a label will adhere to, which dictates and determines surface texture, shape, and surface energy that labels encounter

> Performance properties such as outdoor weathering resistance, which includes UV exposure, high humidity, temperature extremes and even marine conditions

> Printing technology and ink systems used during the production of labels

> Overlaminates and varnishes applied to printed labels, which are employed to protect inks and facestocks from UV light, common chemicals and abrasive conditions.

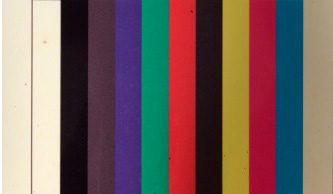

In order to extend the color durability of outdoor products, photosensitive inks must be protected from the sun. Adding a overlaminates to the label is an effective method.

Overlaminate films help extend label durability by absorbing and reflecting portions of UV and visible light that may damage the film and cause the color to fade. They also protect printed labels against the effects of humidity, ozone, chemicals and abrasion.

Digital printing inks exposed to outdoor conditions:

With overlamination

Without overlamination

Testing to specific conditions

There is no one-size-fits-all test for outdoor labels. The label construction must be specified, tested and approved separately for each application. Label materials perform differently when they are applied to different substrates — such as aluminum, steel or polypropylene — or when they are combined with a protective overlaminate film or coating. As a result, it is essential to test the performance of all of the label components working together, using production-intended parts to simulate the planned application and durability.

Many laboratories, including independent laboratories or in-house laboratories of contract manufacturers or materials manufacturers, perform conditioning testing of outdoor labels based on industry standards and end-user specifications.

The most common conditioning tests include:

» Accelerated weathering

» Climate cycling

» Water resistance

» High humidity exposure

» Oven aging and freezer aging

» Salt spray exposure

» Immersion in chemicals or cleaners

To accelerate this process for the long times of label properties testing, brands owners should consider working with a label supplier for their own testing needs. Experienced suppliers have the expertise required to perform each of the necessary tests and are familiar with a variety of materials and tests.

Requirements for outdoor labels are constantly evolving to ensure they have better durability and can keep up with product innovation. Meeting these more stringent performance requirements requires the use of more specialized materials, which often results in higher costs for brands. Accurately selecting the right materials for a specific product is key to controlling costs.

By understanding the impact of different variables on label performance, brands can push durability to new limits by selecting label materials that are cost-effective, durable and strong enough to meet their stringent requirements.

Ruilabels is committed to developing cost-effective outdoor labeling solutions to meet the most demanding durability challenges. Please contact and let us discuss and select a durable labeling solution for your outdoor product application needs.