Ethylene oxide (ETO) has been widely used as a low temperature sterilant since the 1950s. It has been the most common method for sterilizing temperature- and humidity-sensitive medical equipment and supplies in Healthcare facilities. There are two types of ETO sterilizers , mixed gas and 100% ETO. Until 1995, ethylene oxide sterilizers combined ETO with a chlorofluorocarbon (CFC) stabilizer, the most common being 12% ETO mixed with 88% CFC (called 12/88 ETO).

Basic Principles of ETO/EO Sterilization

ETO/EO can kill a variety of microorganisms, including bacterial propagules, spores, viruses and fungal spores, and is a broad-spectrum sterilant. It is generally believed to be due to its non-specific alkylation with microbial proteins, DNA and RNA (non2specific alkylation). ETO/EO in aqueous solution can undergo alkylation with free carboxyl groups (COOH groups (2NH2), sulfhydryl groups (2SH) and hydroxyl groups (2OH) on proteins, replacing unstable hydrogen atoms to form hydroxyethyl groups (CH2CH2OH). ) compounds, the group on the protein is alkylated, so that the protein loses the reactive group required in the basic metabolism, which hinders the normal chemical reaction and metabolism of the bacterial protein, resulting in the death of microorganisms.

Benifits of ETO/EO Sterilization

1. It can be used for sterilization of items that are not resistant to high temperature and moisture.

2. Ethylene oxide is considered to be a chemical sterilant with the best sterilization effect, which can kill all microorganisms including bacterial spores.

3. It has strong penetrability and can be used for sterilization of various difficult-to-penetrate parts: for example, some thinner and longer catheters are difficult to achieve sterilization effect by other low-temperature sterilization methods, and only ETO/EO or irradiation can be used.

4. Small damage to items, because ETO/EO kills microorganisms by using the principle of alkylation instead of oxidation process, so the damage to items is very small, and it has a very wide range of uses for sterilization of heat-labile precision instruments.

5. During sterilization, it can be wrapped with various wrapping materials, which is convenient for storage and transportation. It can be used after opening the package to avoid the risk of cross-contamination.

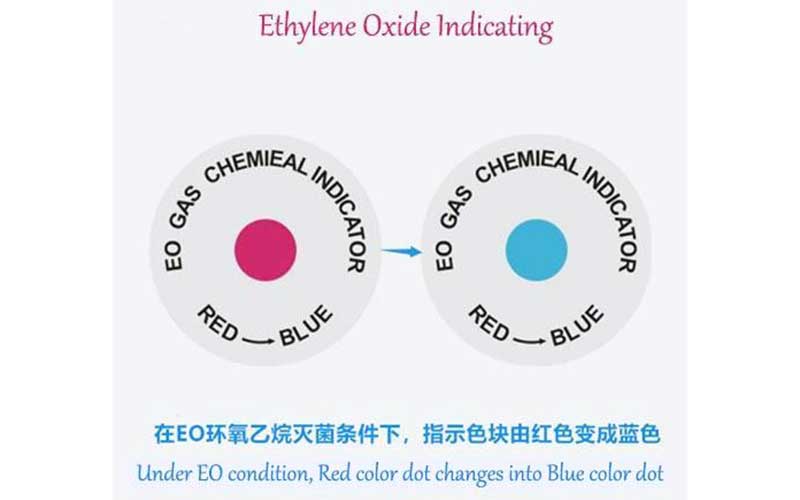

6. There are standard chemical and biological monitoring methods, so that the quality of sterilization can be effectively controlled, and the packages that fail to sterilize can be found in time.

Scope of Application of ETO/EO Sterilization

1. Rigid and flexible endoscopy: arthroscopy, bronchoscopy, cystoscopy, gastroscope, colonoscopy, mediastinoscopy, ophthalmoscopy, otoscope, pharyngoscopy, proctoscopy, prostatectomy, thoracoscopy, urethroscopy.

2. Medical equipment: anesthesia equipment, artificial kidney, diathermy equipment, wires, watch heads, heart-lung machines, breathing, treatment equipment, hemodialysis.

3. Instruments: electric drill, electric burner, electric knife pen, dental drill, microsurgical instruments, nerve stimulators, pressure gauges, surgical instruments, bone drills, needles, artificial joints.

4. Rubber products: catheters, dilators, drainage tubes, endotracheal tubes, surgical gloves, sheets.

5. Plastic products: airway intubation, dilator, endotracheal intubation gloves, pacemaker, heart valve, nebulizer, petri dish, syringe.

6. Other books, toys, linear probes, probes, thermometers, sutures.

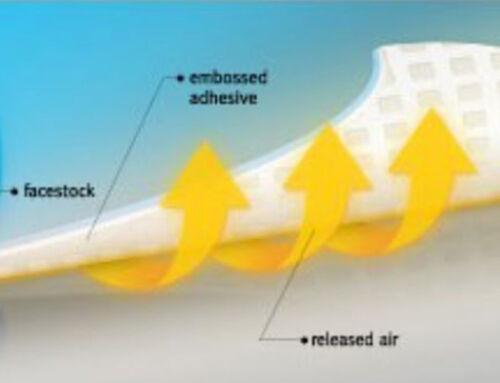

Ruilabels is a professional label supplier in China. We offer labels stickers for ETO/EO Sterilization Applications Solutions . Welcome to contact us buy the high quality label with competitive price.