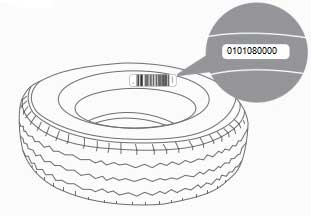

During tire production, tire manufacturers apply a barcode label to the side of the tire to track raw materials and process details throughout the supply chain. This barcode label is attached to the unvulcanized “tire blank” and subsequently integrated into the tire during the vulcanization process.

Ruilabels’s Vulcanization Labeling Solutions

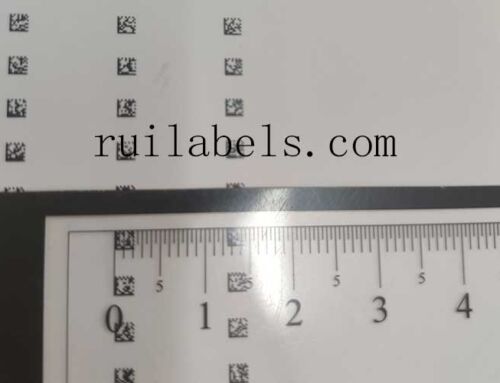

Ruilabels vulcanized labels specailly designed for tire production, the labels bond to the tire during the curing process and maintain excellent adhesion and readability throughout its life circle.

Ruilabels’s tire vulcanized labels are proven to offer the following advantages:

- Excellent barcode/heat transfer printing

- Excellent adhesion

- Ability to withstand the pressure and temperature of the curing process (up to 200°C)

- Durable, high abrasion and chemical resistance (acids, alkalis, salts, low fat solvents)

Ruilabels’s tire vulcanization barcode tracking labels offer outstanding wear and heat resistance, and their excellent readability ensures that tires can be tracked throughout the supply chain.

The vulcanization process is an important part of the tire manufacturing process, where the uncured “tire blanks” is placed in a curing press for hot pressing, resulting in a finished tire with patterns, lettering and tread patterns. Ruilisibo’s labels are designed to handle the rigors of tire inspection, sorting and shipping, enhancing your product traceability needs throughout the manufacturing process.

Ruilabels provide made-to-order labeling solutions to address your unique labeling needs. For more information about tire vulcanization labelling solutions, please feel free to contact us.