-

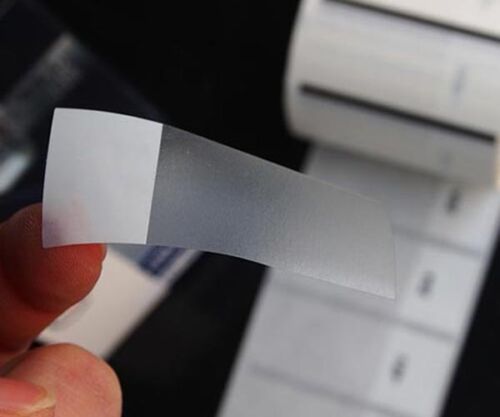

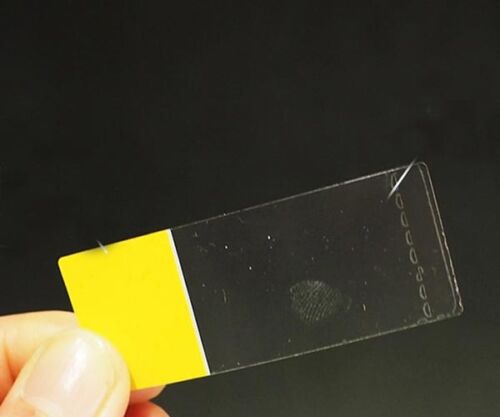

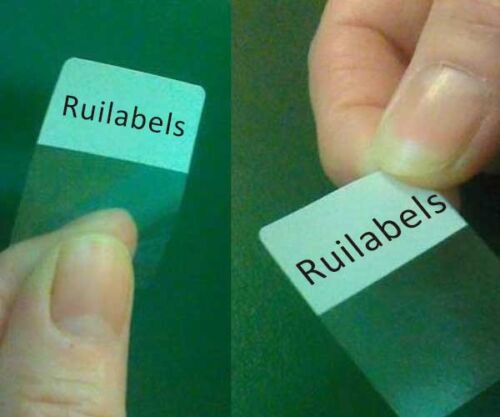

These wrap around self laminating labels are made from durable polyester and can be printed on using laser printers. They are extremely durable and can withstand high temperatures allowing them to be used both indoors and outdoors. Print or write what you need to on the white area of your label, then protect it from damage by wrapping clear laminate over it.

These wrap around self laminating labels are made from durable polyester and can be printed on using laser printers. They are extremely durable and can withstand high temperatures allowing them to be used both indoors and outdoors. Print or write what you need to on the white area of your label, then protect it from damage by wrapping clear laminate over it. -

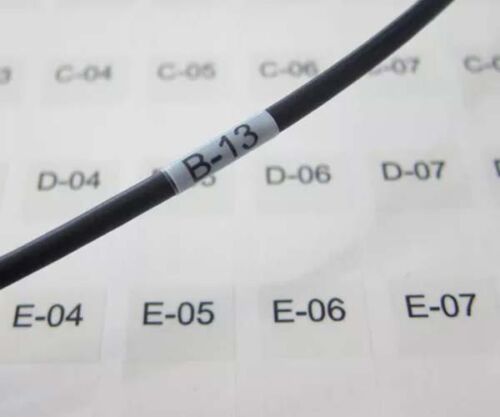

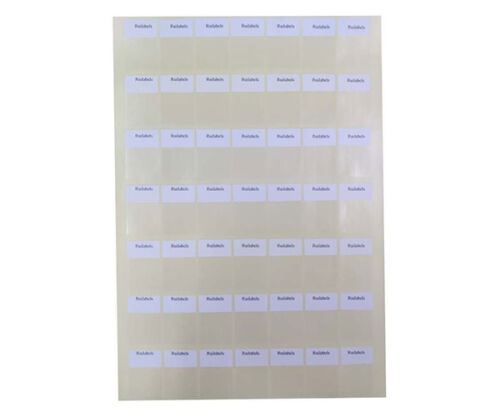

Audio cable labels consist of a white printable and a transparent lamination. This guarantees excellent protection of the printed text against moisture, dirt, deposits and mechanical wear. Due to their flexibility, most of these labels are also suitable for flat ribbon cables, and some of them are suitable for high temperature and outdoor requirements.

Audio cable labels consist of a white printable and a transparent lamination. This guarantees excellent protection of the printed text against moisture, dirt, deposits and mechanical wear. Due to their flexibility, most of these labels are also suitable for flat ribbon cables, and some of them are suitable for high temperature and outdoor requirements. -

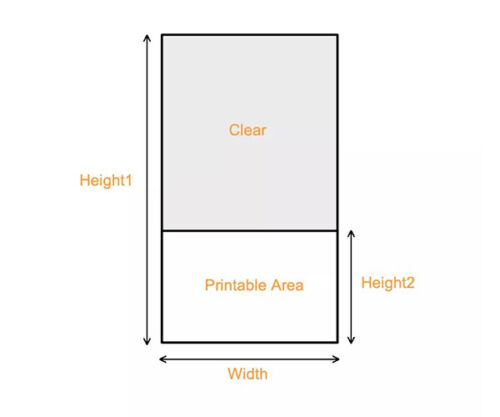

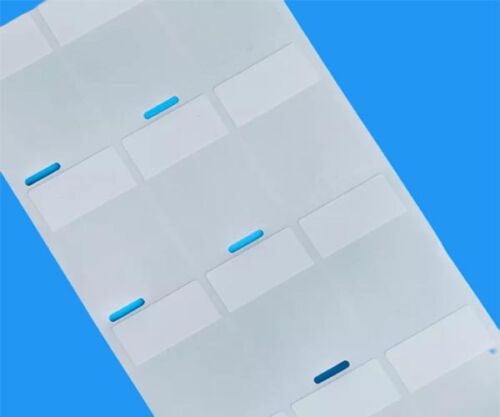

Cable & wire labels are designed to wrap cables and laminate themselves upon application to create durable, easy-to-read cable labels. They are designed for printing on laser printers, the top third of the cable label is the print area, and the bottom two thirds of the cable label are clear polyester that covers the printed portion once applied.

Cable & wire labels are designed to wrap cables and laminate themselves upon application to create durable, easy-to-read cable labels. They are designed for printing on laser printers, the top third of the cable label is the print area, and the bottom two thirds of the cable label are clear polyester that covers the printed portion once applied. -

It is a clear vinyl film with a white thermal transfer printable area. On application, the clear film over-laminates and protects the printed area. The label is supplied with a permanent acrylic based adhesive and on a white liner with reference holes for printer sensor detection. The “self laminating” feature protects the printed area from exposure to fluids, moisture and mechanical abrasion.

It is a clear vinyl film with a white thermal transfer printable area. On application, the clear film over-laminates and protects the printed area. The label is supplied with a permanent acrylic based adhesive and on a white liner with reference holes for printer sensor detection. The “self laminating” feature protects the printed area from exposure to fluids, moisture and mechanical abrasion. -

These labels are designed to wrap round the cable, laminating it as they are applied to create durable, easy-to-read cable labels. The top third of our cable labels are the printable area, and the bottom two thirds of our cable labels are transparent polyester which over-laminates the printed part once applied. Ideal for every cable and wire identification project.

These labels are designed to wrap round the cable, laminating it as they are applied to create durable, easy-to-read cable labels. The top third of our cable labels are the printable area, and the bottom two thirds of our cable labels are transparent polyester which over-laminates the printed part once applied. Ideal for every cable and wire identification project. -

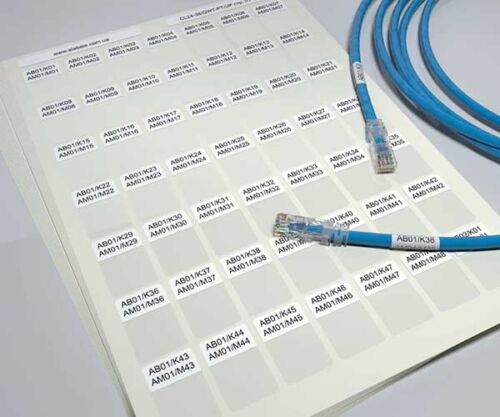

Network Cabling Cable Labels are a white or color printing coating and the other part is a transparent protective film. The transparent protective film covers and wraps the labels to prevent friction damage during wiring. The diameter of the cable determines the length of the protective film. Normally, wrap the cable for one or two turns at the 5-8 cm place of the cable connector.

Network Cabling Cable Labels are a white or color printing coating and the other part is a transparent protective film. The transparent protective film covers and wraps the labels to prevent friction damage during wiring. The diameter of the cable determines the length of the protective film. Normally, wrap the cable for one or two turns at the 5-8 cm place of the cable connector.