-

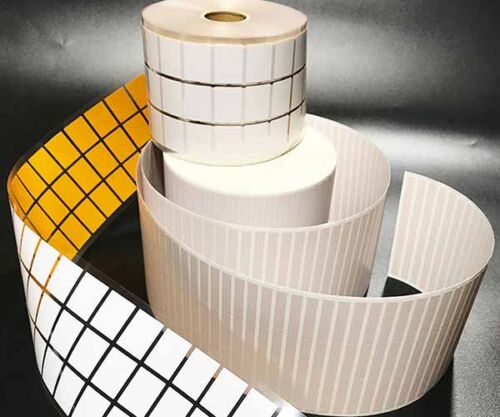

Marking labels for circuit boards, the labels withstand extreme temperature spikes during soldering and ensure tracking during production. The labels are extremely robust and resistant to cleaning processes with hot and aggressive chemicals and high pressure and ultrasonic technology, which remove the remaining soldering flux.

Marking labels for circuit boards, the labels withstand extreme temperature spikes during soldering and ensure tracking during production. The labels are extremely robust and resistant to cleaning processes with hot and aggressive chemicals and high pressure and ultrasonic technology, which remove the remaining soldering flux. -

This self adhesive polyimide label is designed for printed circuit boards or related electronic components used on the characters or Logo and barcode label design. It is in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment to maintain excellence in the performance of an ideal material.

This self adhesive polyimide label is designed for printed circuit boards or related electronic components used on the characters or Logo and barcode label design. It is in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment to maintain excellence in the performance of an ideal material. -

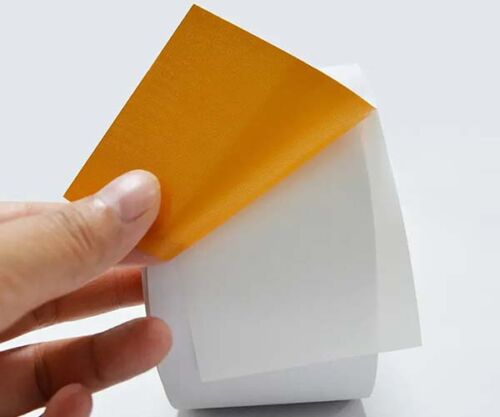

Ruilabels supply PI label material that is made of polyimide film as the base material and coated with special pressure-sensitive adhesive. Its high temperature resistance can withstand up to 300°C. In addition, the label is extremely strong Excellent resistance to friction, dirt, chemicals and harsh environments. Can withstand reflow soldering, wave soldering and high-pressure solvent cleaning with various chemicals.

Ruilabels supply PI label material that is made of polyimide film as the base material and coated with special pressure-sensitive adhesive. Its high temperature resistance can withstand up to 300°C. In addition, the label is extremely strong Excellent resistance to friction, dirt, chemicals and harsh environments. Can withstand reflow soldering, wave soldering and high-pressure solvent cleaning with various chemicals. -

These polyimide barcode labels are designed to operate at higher temperatures than polyester. They can be used for electrical insulation, safety and plating, even on parts over 280°C to 300°C, especially those where lead is restricted from being used in place of protection when handling SMT reflow. PCB lines, LCDs, soldering.

These polyimide barcode labels are designed to operate at higher temperatures than polyester. They can be used for electrical insulation, safety and plating, even on parts over 280°C to 300°C, especially those where lead is restricted from being used in place of protection when handling SMT reflow. PCB lines, LCDs, soldering. -

The polyimide ESD (Electrostatic Discharge) label material is a specialized adhesive label designed to help identify and protect sensitive electronic components and devices from the damaging effects of electrostatic discharge. ESD labels are important because they help to prevent damage to electronic components, reducing the risk of product failure and ensuring the reliability of electronic devices.

The polyimide ESD (Electrostatic Discharge) label material is a specialized adhesive label designed to help identify and protect sensitive electronic components and devices from the damaging effects of electrostatic discharge. ESD labels are important because they help to prevent damage to electronic components, reducing the risk of product failure and ensuring the reliability of electronic devices. -

Ruilabels' polyimide PCB label is abrasion-resistant, will not soften, will not yellow and can withstand the toughest high-reactive fluxes (ORH1). The aggressive, pressure-sensitive adhesive is specially formulated to hold firmly to PCBs and components in wave soldering, reflow soldering and high-pressure cleaning applications.

Ruilabels' polyimide PCB label is abrasion-resistant, will not soften, will not yellow and can withstand the toughest high-reactive fluxes (ORH1). The aggressive, pressure-sensitive adhesive is specially formulated to hold firmly to PCBs and components in wave soldering, reflow soldering and high-pressure cleaning applications. -

The QR code label is based on polyimide film, coated with special pressure-sensitive adhesive, and can withstand high temperatures up to 350°C. The polyimide QR code label have the unique surface semic glossy coating, strong friction, nitrogen resistance, dirt resistance, chemical resistance and harsh environment resistance. The labels can withstand reflow soldering, wave soldering and solvent cleaning of various chemicals under high pressure.

The QR code label is based on polyimide film, coated with special pressure-sensitive adhesive, and can withstand high temperatures up to 350°C. The polyimide QR code label have the unique surface semic glossy coating, strong friction, nitrogen resistance, dirt resistance, chemical resistance and harsh environment resistance. The labels can withstand reflow soldering, wave soldering and solvent cleaning of various chemicals under high pressure.