-

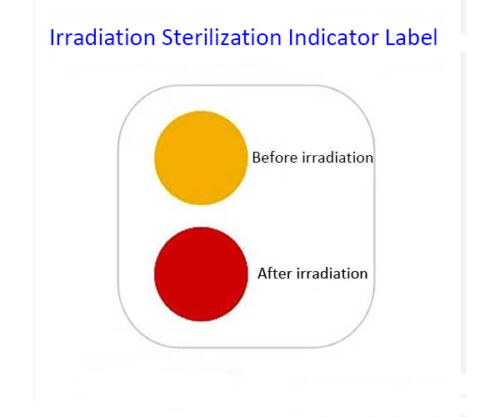

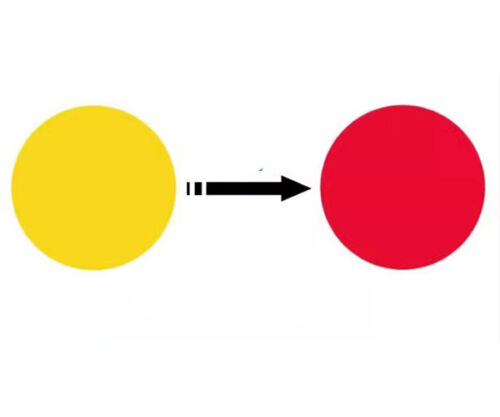

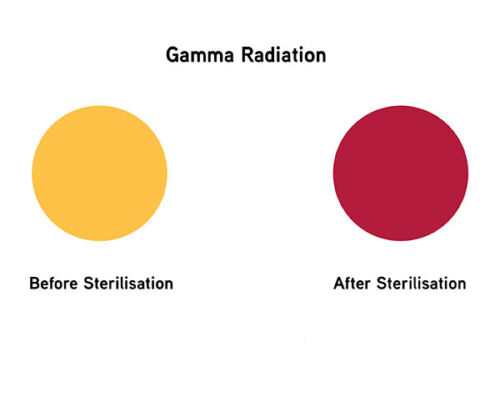

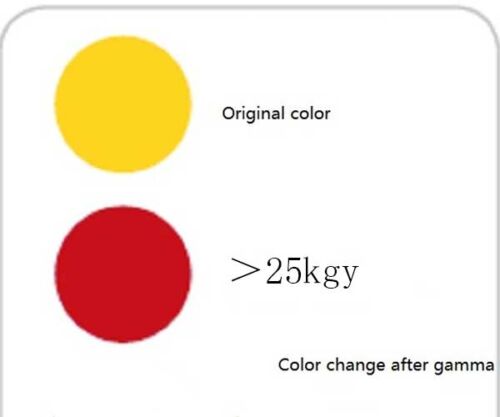

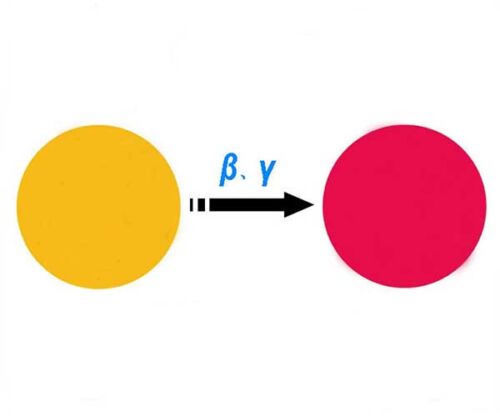

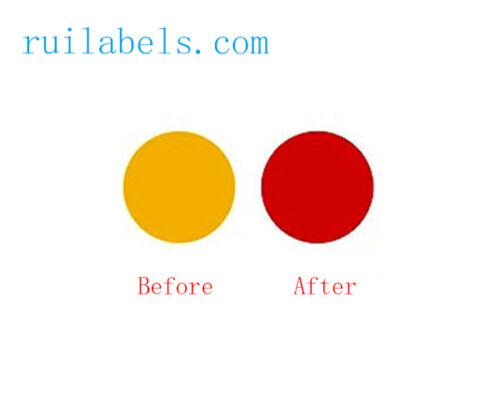

This chemical indicator for the sterilization process, the color change is irreversible from yellow to red. By observing the color change of the label, we can determine whether the item on which the label is pasted has been irradiated by gamma rays, and whether the intensity of the irradiation has reached the standard.

This chemical indicator for the sterilization process, the color change is irreversible from yellow to red. By observing the color change of the label, we can determine whether the item on which the label is pasted has been irradiated by gamma rays, and whether the intensity of the irradiation has reached the standard. -

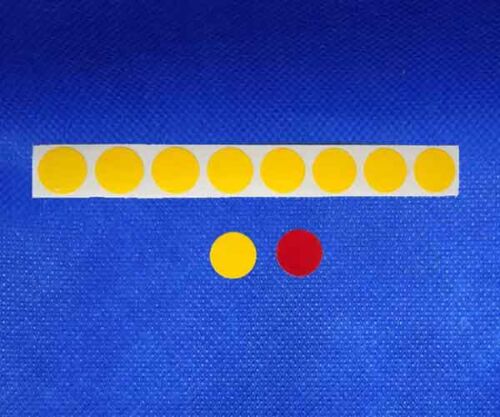

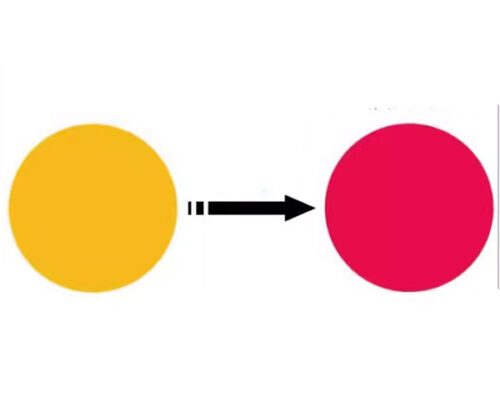

Ruilabels E-Beam Irradiation Sterilization Label turns from orange to almost positive red at about 10kGy, and slowly deepens with the increase of accumulated absorbed dose until it turns into deep red. It is used for visual quality control of irradiated processes to determine if the product has been properly irradiated.

Ruilabels E-Beam Irradiation Sterilization Label turns from orange to almost positive red at about 10kGy, and slowly deepens with the increase of accumulated absorbed dose until it turns into deep red. It is used for visual quality control of irradiated processes to determine if the product has been properly irradiated. -

These indicator labels will undergo a colour change from yellow to red when exposed to gamma radiation. There is a noticeable colour change at 10 kGy with the colour becoming darker with increased dose levels. This provides a visual indicator that the product has been sterilised and clearly distinguishes a sterile product from one that is not. Applications of this immediate “yes/no” indicator of gamma exposure include food irradiation and the sterilization of medical and surgical products.

These indicator labels will undergo a colour change from yellow to red when exposed to gamma radiation. There is a noticeable colour change at 10 kGy with the colour becoming darker with increased dose levels. This provides a visual indicator that the product has been sterilised and clearly distinguishes a sterile product from one that is not. Applications of this immediate “yes/no” indicator of gamma exposure include food irradiation and the sterilization of medical and surgical products. -

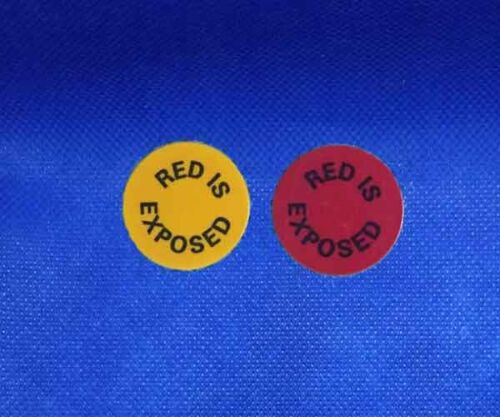

The gamma sterilisation indicator stickers will colour change when exposed to Gamma or E-Beam radiation. Ruilabels supply the plain gamma indicator dots that will undergo a clear and distinct colour change from yellow to red when activated. There are used in such applications as food irradiation and in medical and surgical applications.

The gamma sterilisation indicator stickers will colour change when exposed to Gamma or E-Beam radiation. Ruilabels supply the plain gamma indicator dots that will undergo a clear and distinct colour change from yellow to red when activated. There are used in such applications as food irradiation and in medical and surgical applications. -

The gamma sterilization indicators are suitable for irradiation sterilization in hospitals, pharmaceuticals, food, health products, beverages, hygiene and epidemic prevention, medical device manufacturers and sterilization service agencies. They are used to indicate whether the sterilization package has undergone irradiation sterilization.

The gamma sterilization indicators are suitable for irradiation sterilization in hospitals, pharmaceuticals, food, health products, beverages, hygiene and epidemic prevention, medical device manufacturers and sterilization service agencies. They are used to indicate whether the sterilization package has undergone irradiation sterilization. -

Ruilabels gamma sterilization stickers are manufactured to monitor whether Gamma and E-Beam exposure conditions were met at the point of application using pressure sensitive adhesive. the stickes are intended for use with individual units (e.g. packs, containers) to indicate that the unit has been directly exposed to Gamma and E-Beam process and to distinguish between processed and unprocessed units.

Ruilabels gamma sterilization stickers are manufactured to monitor whether Gamma and E-Beam exposure conditions were met at the point of application using pressure sensitive adhesive. the stickes are intended for use with individual units (e.g. packs, containers) to indicate that the unit has been directly exposed to Gamma and E-Beam process and to distinguish between processed and unprocessed units.