-

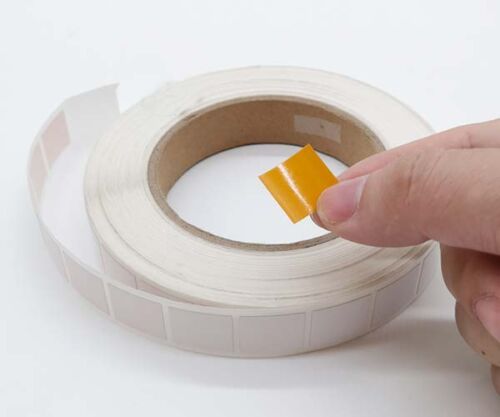

The anti-static polyimide labels for the electronics industry is designed to solve the two major electrostatic discharge (ESD) problems that may exist in standard labels. It can minimize the friction charge generated when peeling the label from the backing paper, and prevent the charge from accumule.ating on the label by eliminating the charge on the label surface.

The anti-static polyimide labels for the electronics industry is designed to solve the two major electrostatic discharge (ESD) problems that may exist in standard labels. It can minimize the friction charge generated when peeling the label from the backing paper, and prevent the charge from accumule.ating on the label by eliminating the charge on the label surface. -

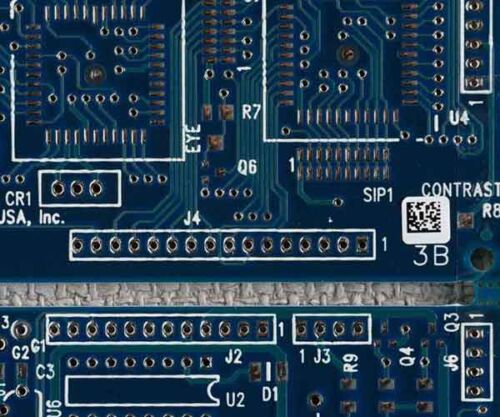

This automatic labeling label is used for the SMT surface mount manufacturing process of PCB circuit boards. It is a special label for PCB identification (the normal application is temperature resistance of 260 ° C for 6 minutes). No blistering, no warping, no glue falling, no yellowing, and it is not easy to be corroded by various chemicals in the flux. It can also be used in electronics, electrical, automotive, aviation and other environments that have higher temperature requirements for materials.

This automatic labeling label is used for the SMT surface mount manufacturing process of PCB circuit boards. It is a special label for PCB identification (the normal application is temperature resistance of 260 ° C for 6 minutes). No blistering, no warping, no glue falling, no yellowing, and it is not easy to be corroded by various chemicals in the flux. It can also be used in electronics, electrical, automotive, aviation and other environments that have higher temperature requirements for materials. -

Excellent temperature resistance, up to 350℃ high temperature resistance; Easy to peel, automatic labeling without paper jam; Chemical resistance, resistance to flux, melting agent, cleaning agent; Ultra-fine printing, no residual glue; Good coating treatment and weather resistance, no delamination, deformation and yellowing after passing through the furnace.

Excellent temperature resistance, up to 350℃ high temperature resistance; Easy to peel, automatic labeling without paper jam; Chemical resistance, resistance to flux, melting agent, cleaning agent; Ultra-fine printing, no residual glue; Good coating treatment and weather resistance, no delamination, deformation and yellowing after passing through the furnace. -

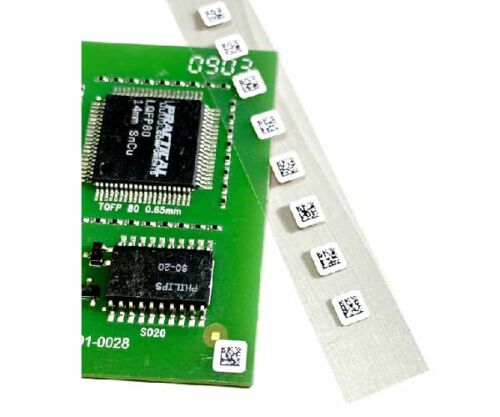

The blank PCB labels are made of high temperature Polyimide with permanent acrylic adhesive. The labels are packed in roll, for use with thermal transfer printers. The labels are deisgned to meet and exceed the high temperature requirements required by reflow soldering and wave soldering environments. And they are resist corrosive fluxes and multiple rounds of cleaning common in circuit board applications.

The blank PCB labels are made of high temperature Polyimide with permanent acrylic adhesive. The labels are packed in roll, for use with thermal transfer printers. The labels are deisgned to meet and exceed the high temperature requirements required by reflow soldering and wave soldering environments. And they are resist corrosive fluxes and multiple rounds of cleaning common in circuit board applications. -

These adhesive polyimide labels are designed to identify high temperature products such as printed circuit boards and related electronic components where solder or wave soldering processes are used, or where the product will be chemically cleaned. Based on pressure-sensitive acrylic adhesives, these labels provide excellent bar code readability after chemical and high temperature exposure.

These adhesive polyimide labels are designed to identify high temperature products such as printed circuit boards and related electronic components where solder or wave soldering processes are used, or where the product will be chemically cleaned. Based on pressure-sensitive acrylic adhesives, these labels provide excellent bar code readability after chemical and high temperature exposure. -

Polyimide label is designed for printed circuit boards or related electronic components used on the characters or barcode label design. It is in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment to maintain excellence in the performance of an ideal material.

Polyimide label is designed for printed circuit boards or related electronic components used on the characters or barcode label design. It is in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment to maintain excellence in the performance of an ideal material. -

The electronic board labels are used in the SMT manufacturing process of PCB circuit boards. The labels are special for PCB identification. It will not bubble, warp, fall off, turn yellow, and is not easily corroded by various chemical substances in the flux. It can also be used in electronics, electrical, automotive, aviation and other environments with high temperature requirements for materials.

The electronic board labels are used in the SMT manufacturing process of PCB circuit boards. The labels are special for PCB identification. It will not bubble, warp, fall off, turn yellow, and is not easily corroded by various chemical substances in the flux. It can also be used in electronics, electrical, automotive, aviation and other environments with high temperature requirements for materials.