-

SMT Tracking Label is used in the SMT manufacturing process of PCB circuit boards. It is a special label for PCB identification (normal applicated temperature resistance of 260 ° C for 6 minutes). No blistering, no warping, no glue falling, no yellowing, and not easy to be corroded by various chemicals in the flux. It can also be used in electronics, electrical, automotive, aviation and other environments that have higher temperature requirements for materials.

SMT Tracking Label is used in the SMT manufacturing process of PCB circuit boards. It is a special label for PCB identification (normal applicated temperature resistance of 260 ° C for 6 minutes). No blistering, no warping, no glue falling, no yellowing, and not easy to be corroded by various chemicals in the flux. It can also be used in electronics, electrical, automotive, aviation and other environments that have higher temperature requirements for materials. -

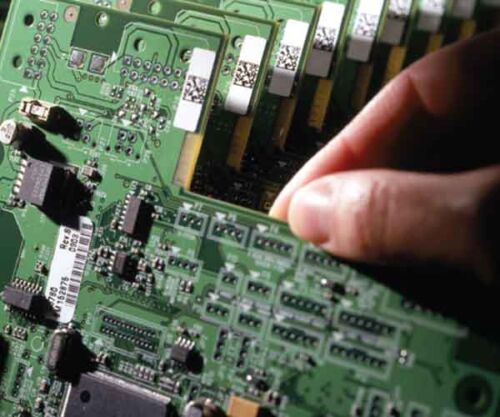

Polyimide labels for electronic circuit boards are based on ultra-thin films. Suitable for high temperature applications such as electronic circuit boards, PCBs, steel, aluminum, etc. The high temperature labels have the characteristics of high temperature resistance, water resistance, oil resistance and corrosion resistance.

Polyimide labels for electronic circuit boards are based on ultra-thin films. Suitable for high temperature applications such as electronic circuit boards, PCBs, steel, aluminum, etc. The high temperature labels have the characteristics of high temperature resistance, water resistance, oil resistance and corrosion resistance.