-

The electronic board labels are used in the SMT manufacturing process of PCB circuit boards. The labels are special for PCB identification. It will not bubble, warp, fall off, turn yellow, and is not easily corroded by various chemical substances in the flux. It can also be used in electronics, electrical, automotive, aviation and other environments with high temperature requirements for materials.

The electronic board labels are used in the SMT manufacturing process of PCB circuit boards. The labels are special for PCB identification. It will not bubble, warp, fall off, turn yellow, and is not easily corroded by various chemical substances in the flux. It can also be used in electronics, electrical, automotive, aviation and other environments with high temperature requirements for materials. -

These heat resistant PCB labels are mainly used for internal process management labels, logistics management labels, and product display labels in harsh environments that require heat resistance, such as semiconductor manufacturing processes and printed circuit board management manufacturing processes.

These heat resistant PCB labels are mainly used for internal process management labels, logistics management labels, and product display labels in harsh environments that require heat resistance, such as semiconductor manufacturing processes and printed circuit board management manufacturing processes. -

PCB traceability labels are deaigned for tracking on printed circuit boards and electronic components through the entire assembly workflow. The labels consist of a top-coated semi-gloss polyimide material and permanent acrylic adhesive. It can endure harsh environments such as high heat, aggressive fluxes, and caustic cleaners commonly used in the manufacturing process.

PCB traceability labels are deaigned for tracking on printed circuit boards and electronic components through the entire assembly workflow. The labels consist of a top-coated semi-gloss polyimide material and permanent acrylic adhesive. It can endure harsh environments such as high heat, aggressive fluxes, and caustic cleaners commonly used in the manufacturing process. -

Our heat resistant polyimide label uses 1mil or 2mil polyimide film with acrylic adhesive. The matte white thermal transfer topcoat is easy to read for all kinds of bar codes and other variable information. It can withstand short high temperature up to 350°and long term temperature to 280°. It can be applied on various application such as PCB Board tracking, other bar code tracking, surface protection and masking like wave solder masking, SMT processing, lithium battery or chip packaging protection.

Our heat resistant polyimide label uses 1mil or 2mil polyimide film with acrylic adhesive. The matte white thermal transfer topcoat is easy to read for all kinds of bar codes and other variable information. It can withstand short high temperature up to 350°and long term temperature to 280°. It can be applied on various application such as PCB Board tracking, other bar code tracking, surface protection and masking like wave solder masking, SMT processing, lithium battery or chip packaging protection. -

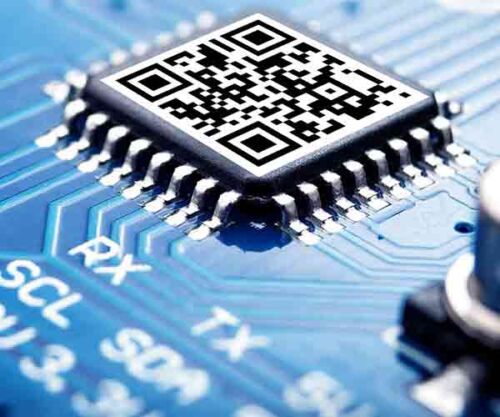

Heat resistant QR labels help electronic equipment manufacturers keep track of PCBs during production, storage, and installation, ensuring they use the right components in their products. Our high quality labels can minimise the risk of downtime and costs to ensure the full manufacture traceability.

Heat resistant QR labels help electronic equipment manufacturers keep track of PCBs during production, storage, and installation, ensuring they use the right components in their products. Our high quality labels can minimise the risk of downtime and costs to ensure the full manufacture traceability. -

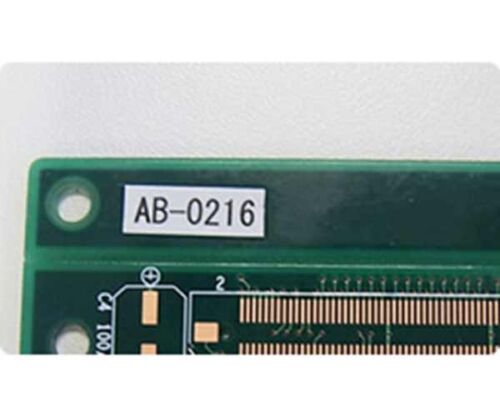

Ruilabels heat-resistant PCB labels are designed for printed circuit boards or related electronic components used on the characters and barcode label design. It is an ideal label material in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment.

Ruilabels heat-resistant PCB labels are designed for printed circuit boards or related electronic components used on the characters and barcode label design. It is an ideal label material in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment. -

Ruilabels has developed high pressure water clearning labels that are typical of PCB post-production cleaning processes. This label provides critical identification and traceability of PCB assemblies, is exceptionally durable against smudges, solvents, heat and abrasion and can be printable with all brands of thermal transfer printers.

Ruilabels has developed high pressure water clearning labels that are typical of PCB post-production cleaning processes. This label provides critical identification and traceability of PCB assemblies, is exceptionally durable against smudges, solvents, heat and abrasion and can be printable with all brands of thermal transfer printers.