-

Using advanced raw materials as the substrate, coated with color-changing ink as sterilization indicator, back coated with pressure-sensitive adhesive release paper. Sterilization label can be directly pasted on the surface of the sterilized item package, and the label can be strengthened by light pressure. It can also be recorded on the label with the available ballpoint pen and marker pen, which is easy to manage.

Using advanced raw materials as the substrate, coated with color-changing ink as sterilization indicator, back coated with pressure-sensitive adhesive release paper. Sterilization label can be directly pasted on the surface of the sterilized item package, and the label can be strengthened by light pressure. It can also be recorded on the label with the available ballpoint pen and marker pen, which is easy to manage. -

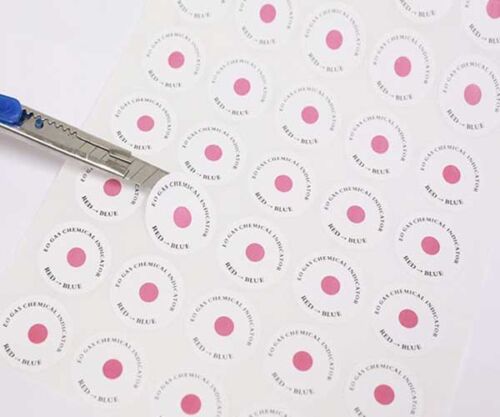

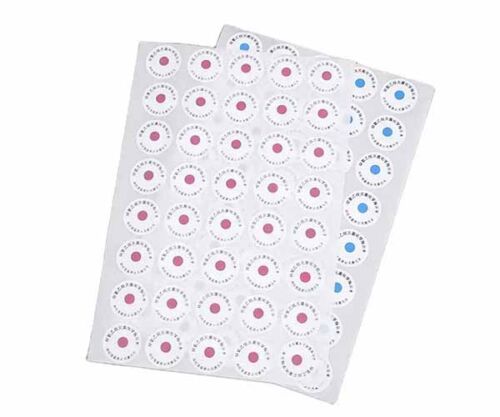

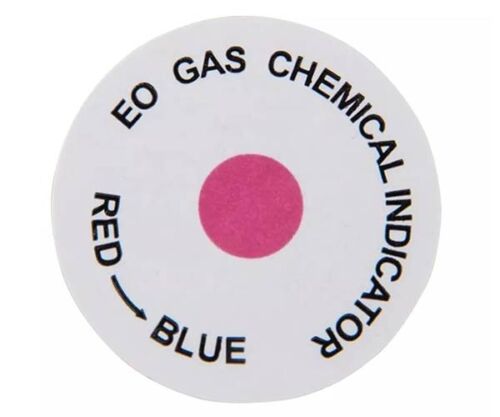

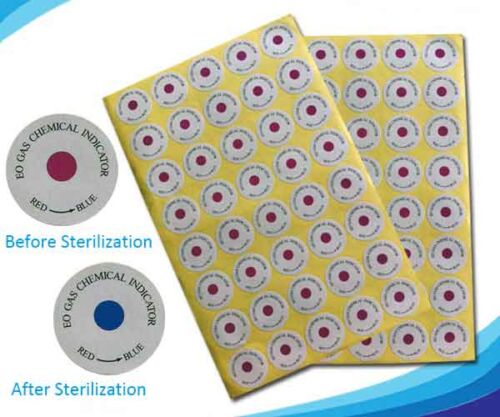

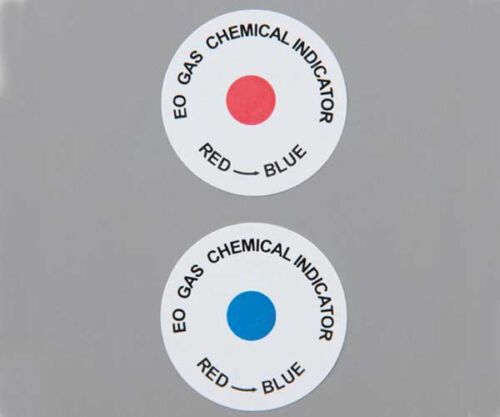

The EO indicators are made of imported paper as the base material, coated with color-changing ink as a sterilization indicator, and back-coated with pressure-sensitive adhesive and release paper. Under the required sterilization conditions, the color of the indicator color changes from red to blue, and the color after sterilization is not easy to fade.

The EO indicators are made of imported paper as the base material, coated with color-changing ink as a sterilization indicator, and back-coated with pressure-sensitive adhesive and release paper. Under the required sterilization conditions, the color of the indicator color changes from red to blue, and the color after sterilization is not easy to fade. -

EO sterilization indicator label is used for hospitals, medical devices, food and other departments of ethylene oxide sterilizer. The chemical indicator printed on the surface of the label will undergo chemical changes when it reaches the set temperature and time under the action of ethylene oxide, accompanied by a color change.

EO sterilization indicator label is used for hospitals, medical devices, food and other departments of ethylene oxide sterilizer. The chemical indicator printed on the surface of the label will undergo chemical changes when it reaches the set temperature and time under the action of ethylene oxide, accompanied by a color change. -

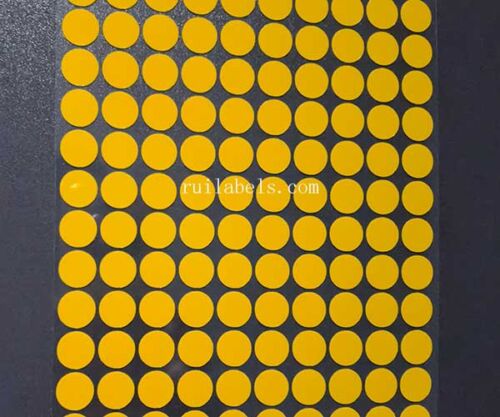

EO Sterilization Labels are a circle with chemical dyes, ethylene oxide concentration of 600 mg/L, temperature 54 degrees celsius and 50% relative humidity conditions, 2 hours to completely change color when color is blue (endpoint color), indicate that the sterilization process meets the requirements, if the color has not reached the endpoint, indicate that the sterilization process does not conform to the requirements.

EO Sterilization Labels are a circle with chemical dyes, ethylene oxide concentration of 600 mg/L, temperature 54 degrees celsius and 50% relative humidity conditions, 2 hours to completely change color when color is blue (endpoint color), indicate that the sterilization process meets the requirements, if the color has not reached the endpoint, indicate that the sterilization process does not conform to the requirements. -

Ethylene Oxide indicator labels are applied to sterilization test. It is made of special paper especially for medical use. There is a color on the product which is a chemical and color-reflective agent. It is put in the package of medical devices to test whether it has been sterilized by Ethylene Oxide or to know whether Ethylene Oxide can come into contact with the inside of the device. The process of changing color is accurate and precise of the 30 mm diameter indicator strip.

Ethylene Oxide indicator labels are applied to sterilization test. It is made of special paper especially for medical use. There is a color on the product which is a chemical and color-reflective agent. It is put in the package of medical devices to test whether it has been sterilized by Ethylene Oxide or to know whether Ethylene Oxide can come into contact with the inside of the device. The process of changing color is accurate and precise of the 30 mm diameter indicator strip. -

The round chemical indicator ink printed on the label surface will undergo chemical changes and color changes when the set temperature and time are reached under the action of ethylene oxide. The depth of its color is closely related to the concentration, temperature and duration of ethylene oxide. According to the color development effect of the indicator ink, it can be confirmed whether the indicated items have been sterilized accordingly.

The round chemical indicator ink printed on the label surface will undergo chemical changes and color changes when the set temperature and time are reached under the action of ethylene oxide. The depth of its color is closely related to the concentration, temperature and duration of ethylene oxide. According to the color development effect of the indicator ink, it can be confirmed whether the indicated items have been sterilized accordingly. -

ETO Sterilization Label, the circular chemical indicator ink printed on the surface of the label, under the action of ethylene oxide, undergoes a chemical change and is accompanied by a color change when it reaches the set temperature and time. According to the color changing, to confirm whether the indicated items have been sterilized.

ETO Sterilization Label, the circular chemical indicator ink printed on the surface of the label, under the action of ethylene oxide, undergoes a chemical change and is accompanied by a color change when it reaches the set temperature and time. According to the color changing, to confirm whether the indicated items have been sterilized. -

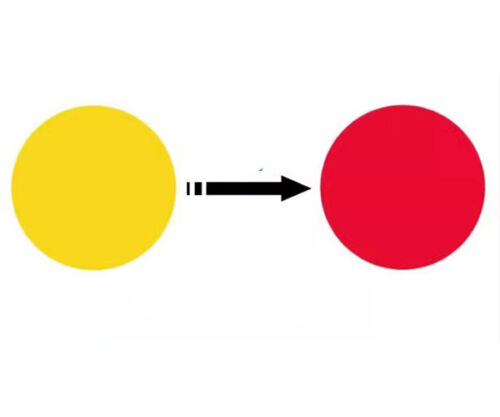

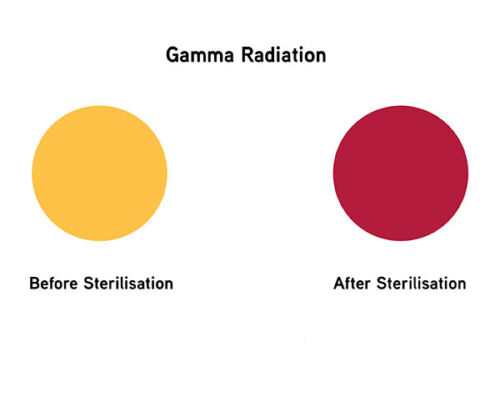

These indicator labels will undergo a colour change from yellow to red when exposed to gamma radiation. There is a noticeable colour change at 10 kGy with the colour becoming darker with increased dose levels. This provides a visual indicator that the product has been sterilised and clearly distinguishes a sterile product from one that is not. Applications of this immediate “yes/no” indicator of gamma exposure include food irradiation and the sterilization of medical and surgical products.

These indicator labels will undergo a colour change from yellow to red when exposed to gamma radiation. There is a noticeable colour change at 10 kGy with the colour becoming darker with increased dose levels. This provides a visual indicator that the product has been sterilised and clearly distinguishes a sterile product from one that is not. Applications of this immediate “yes/no” indicator of gamma exposure include food irradiation and the sterilization of medical and surgical products.