-

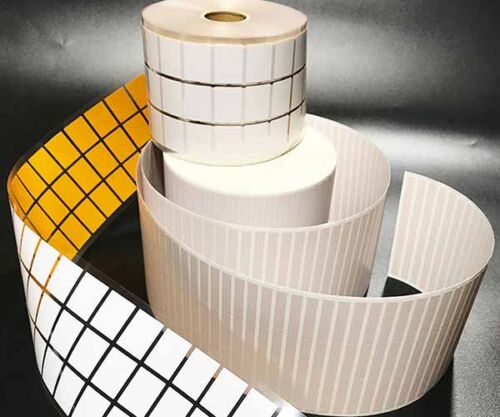

The polyimide ESD (Electrostatic Discharge) label material is a specialized adhesive label designed to help identify and protect sensitive electronic components and devices from the damaging effects of electrostatic discharge. ESD labels are important because they help to prevent damage to electronic components, reducing the risk of product failure and ensuring the reliability of electronic devices.

The polyimide ESD (Electrostatic Discharge) label material is a specialized adhesive label designed to help identify and protect sensitive electronic components and devices from the damaging effects of electrostatic discharge. ESD labels are important because they help to prevent damage to electronic components, reducing the risk of product failure and ensuring the reliability of electronic devices. -

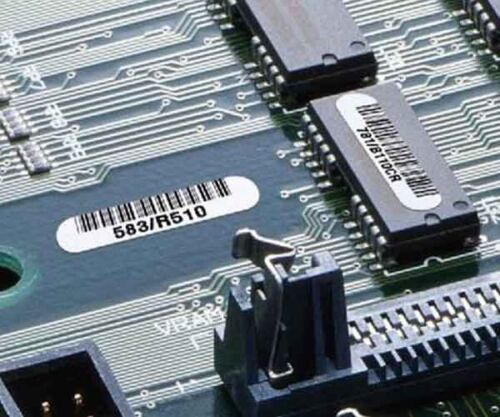

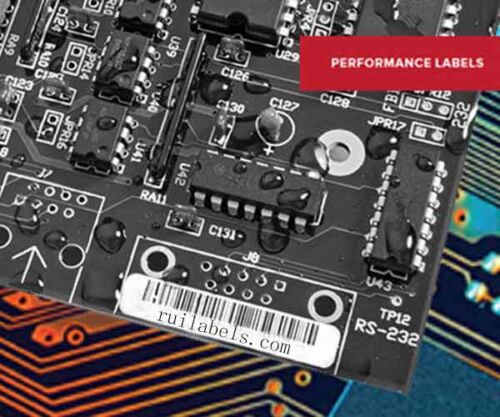

Ruilabels heat resistant polyimide labels have many advantages such as no falling off, no deformation, no discoloration, fire prevention, oil resistance, water resistance, wear resistance, chemical corrosion resistance. Most of them are used in special industrial environments, such as circuit boards, ES computer motherboards, The mobile phone motherboard and PCB circuit are marked with high temperature resistant barcode labels in the wave furnace and reflow soldering.

Ruilabels heat resistant polyimide labels have many advantages such as no falling off, no deformation, no discoloration, fire prevention, oil resistance, water resistance, wear resistance, chemical corrosion resistance. Most of them are used in special industrial environments, such as circuit boards, ES computer motherboards, The mobile phone motherboard and PCB circuit are marked with high temperature resistant barcode labels in the wave furnace and reflow soldering. -

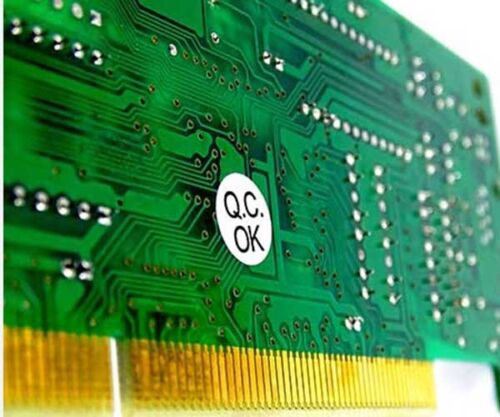

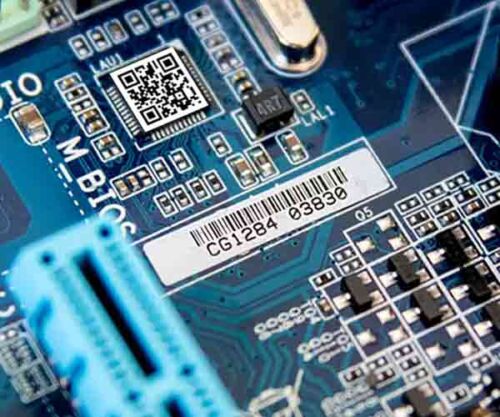

Ruilisibo provides high-performance PCB labels that ensure long-term readability, helping electronic device manufacturers track PCBs during production, storage, and installation. It can be used in environments such as electronics, electrical, automotive, and aviation that require high material temperatures.

Ruilisibo provides high-performance PCB labels that ensure long-term readability, helping electronic device manufacturers track PCBs during production, storage, and installation. It can be used in environments such as electronics, electrical, automotive, and aviation that require high material temperatures. -

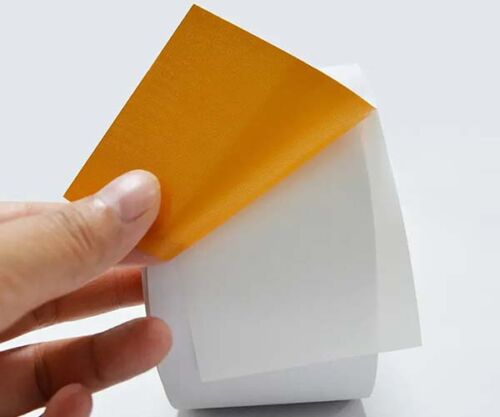

Polyimide kapton labels made of acrylic adhesive with polyimide film. It is designed to be used for electrical insulation, safety, and plating even at parts that are over 280 ℃ to 300. Especially places that are restricted to use lead are substituting to this product for protection while processing SMT reflow, PCB line, LCD, Soldering.

Polyimide kapton labels made of acrylic adhesive with polyimide film. It is designed to be used for electrical insulation, safety, and plating even at parts that are over 280 ℃ to 300. Especially places that are restricted to use lead are substituting to this product for protection while processing SMT reflow, PCB line, LCD, Soldering. -

Ruilabels' polyimide PCB label is abrasion-resistant, will not soften, will not yellow and can withstand the toughest high-reactive fluxes (ORH1). The aggressive, pressure-sensitive adhesive is specially formulated to hold firmly to PCBs and components in wave soldering, reflow soldering and high-pressure cleaning applications.

Ruilabels' polyimide PCB label is abrasion-resistant, will not soften, will not yellow and can withstand the toughest high-reactive fluxes (ORH1). The aggressive, pressure-sensitive adhesive is specially formulated to hold firmly to PCBs and components in wave soldering, reflow soldering and high-pressure cleaning applications. -

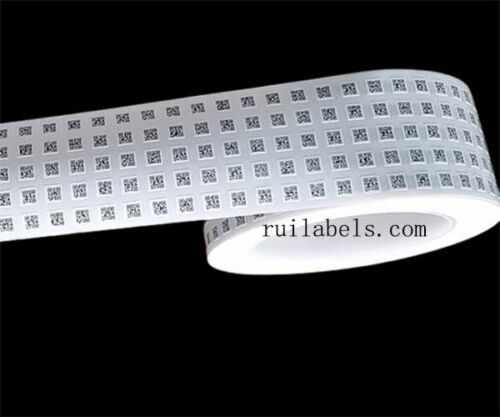

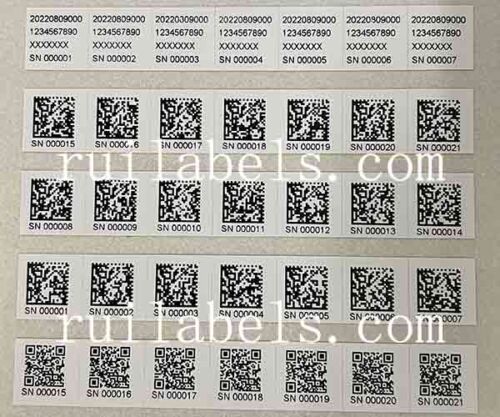

The QR code label is based on polyimide film, coated with special pressure-sensitive adhesive, and can withstand high temperatures up to 350°C. The polyimide QR code label have the unique surface semic glossy coating, strong friction, nitrogen resistance, dirt resistance, chemical resistance and harsh environment resistance. The labels can withstand reflow soldering, wave soldering and solvent cleaning of various chemicals under high pressure.

The QR code label is based on polyimide film, coated with special pressure-sensitive adhesive, and can withstand high temperatures up to 350°C. The polyimide QR code label have the unique surface semic glossy coating, strong friction, nitrogen resistance, dirt resistance, chemical resistance and harsh environment resistance. The labels can withstand reflow soldering, wave soldering and solvent cleaning of various chemicals under high pressure. -

The polyimide thermal transfer labels are designed to operate at elevated temperatures. It can be used for electrical insulation, safety, and plating even atparts that are over 280 Degree to 350 Degree. Especially places that arerestricted to use lead are substituting to this product for protectionwhile processing SMT reflow. PCB line, LCD , Soldering.

The polyimide thermal transfer labels are designed to operate at elevated temperatures. It can be used for electrical insulation, safety, and plating even atparts that are over 280 Degree to 350 Degree. Especially places that arerestricted to use lead are substituting to this product for protectionwhile processing SMT reflow. PCB line, LCD , Soldering. -

These pre-printed data matrix labels are used on PCBs that can survive high temperatures in an SMT reflow oven. Ruilabels labels maintain their physical integrity with excellent high temperature, heat resistant substrate, ensuring that the label remains readable after exposed to harsh environment processing.

These pre-printed data matrix labels are used on PCBs that can survive high temperatures in an SMT reflow oven. Ruilabels labels maintain their physical integrity with excellent high temperature, heat resistant substrate, ensuring that the label remains readable after exposed to harsh environment processing. -

Printed Circuit Board Labeling is to ensure long-term PCB traceability, the legibility and durability requirements are at the heart of selecting a print solution. Ruilabels supply high performace labeling solutions for PCBs. Our labels are 350C high temperature safe. And the labels wont shrink, burn and the printed information stay readable after reflow process.

Printed Circuit Board Labeling is to ensure long-term PCB traceability, the legibility and durability requirements are at the heart of selecting a print solution. Ruilabels supply high performace labeling solutions for PCBs. Our labels are 350C high temperature safe. And the labels wont shrink, burn and the printed information stay readable after reflow process. -

Ruilabels QR code polyimide labels are widely used for permanent labeling of electronic products that are exposed to extreme temperatures during the manufacturing process. Ruilabels polyimide materials utilize the increased rigidity, chemical resistance, high intrinsic dielectric strength and extreme heat resistance of high performance polyimide films for reflow soldering, aggressive aqueous chemical cleaning and device testing.

Ruilabels QR code polyimide labels are widely used for permanent labeling of electronic products that are exposed to extreme temperatures during the manufacturing process. Ruilabels polyimide materials utilize the increased rigidity, chemical resistance, high intrinsic dielectric strength and extreme heat resistance of high performance polyimide films for reflow soldering, aggressive aqueous chemical cleaning and device testing.