-

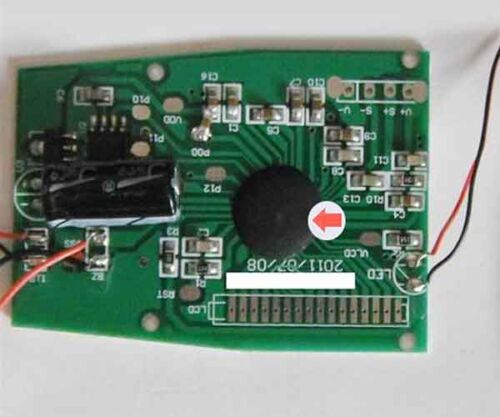

Polyimide label is designed for printed circuit boards or related electronic components used on the characters or Logo and barcode label design. It is in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment to maintain excellence in the performance of an ideal material.

Polyimide label is designed for printed circuit boards or related electronic components used on the characters or Logo and barcode label design. It is in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment to maintain excellence in the performance of an ideal material. -

High temperature resistant polyimide labels are specially formulated for high-temperature solutions with excellent heat resistant qualities that do not degrade under harsh conditions. There are generally used for tracking of electronic chips during wave soldering. They can place a bar code, a serial number, or a Datamatrix code on it.

High temperature resistant polyimide labels are specially formulated for high-temperature solutions with excellent heat resistant qualities that do not degrade under harsh conditions. There are generally used for tracking of electronic chips during wave soldering. They can place a bar code, a serial number, or a Datamatrix code on it. -

The high temperature SMT label can withstand short high temperature up to 320°and long term temperature to 280°. It It has very excellent thermal stability, moisture resistance and good initial tack. Ideal for identification use in high-heat items like circuit boards and related electronic components, where a soldering flux or wave soldering process is used or if the product will be exposed to a chemical cleaning cycle.

The high temperature SMT label can withstand short high temperature up to 320°and long term temperature to 280°. It It has very excellent thermal stability, moisture resistance and good initial tack. Ideal for identification use in high-heat items like circuit boards and related electronic components, where a soldering flux or wave soldering process is used or if the product will be exposed to a chemical cleaning cycle. -

High-Temperature-Resistant Label is made of polyimide film as a base material and coated with a unique pressure-sensitive adhesive. It has good chemical resistance and abrasion resistance. It keeps the product in high temperature environment without warping, peeling and discoloration for a period of time, and the information on the label surface is clear.

High-Temperature-Resistant Label is made of polyimide film as a base material and coated with a unique pressure-sensitive adhesive. It has good chemical resistance and abrasion resistance. It keeps the product in high temperature environment without warping, peeling and discoloration for a period of time, and the information on the label surface is clear. -

Marking labels for circuit boards, the labels withstand extreme temperature spikes during soldering and ensure tracking during production. The labels are extremely robust and resistant to cleaning processes with hot and aggressive chemicals and high pressure and ultrasonic technology, which remove the remaining soldering flux.

Marking labels for circuit boards, the labels withstand extreme temperature spikes during soldering and ensure tracking during production. The labels are extremely robust and resistant to cleaning processes with hot and aggressive chemicals and high pressure and ultrasonic technology, which remove the remaining soldering flux. -

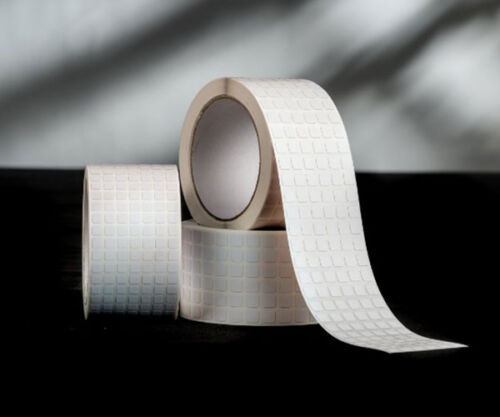

This self adhesive polyimide label is designed for printed circuit boards or related electronic components used on the characters or Logo and barcode label design. It is in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment to maintain excellence in the performance of an ideal material.

This self adhesive polyimide label is designed for printed circuit boards or related electronic components used on the characters or Logo and barcode label design. It is in circuit boards and SMT, DIP during wave solder or reflow to ensure that all kinds of extreme harsh application environment to maintain excellence in the performance of an ideal material.