-

Specifically designed for use on PCBs and electronic components, The PCB labels can withstand harsh environments such as high heat, aggressive fluxes, and caustic cleaners commonly used in the PCB manufacturing process. Materials are intended for top-side, bottom-side, or after-process identification.

Specifically designed for use on PCBs and electronic components, The PCB labels can withstand harsh environments such as high heat, aggressive fluxes, and caustic cleaners commonly used in the PCB manufacturing process. Materials are intended for top-side, bottom-side, or after-process identification. -

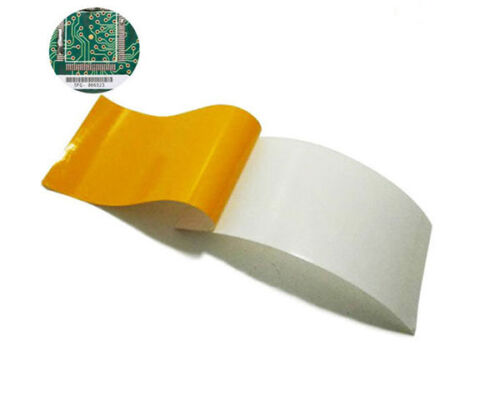

0.375" x 0.375" Polyimide label is high temperature insulating material that is widely used in the electrical and electronic industry for thermal and electrical insulation applications. It withstands high temperatures up to 350°C. And it has no tendency to curl, crease, wrinkle, shrink, turn yellow or burn at high temperatures.

0.375" x 0.375" Polyimide label is high temperature insulating material that is widely used in the electrical and electronic industry for thermal and electrical insulation applications. It withstands high temperatures up to 350°C. And it has no tendency to curl, crease, wrinkle, shrink, turn yellow or burn at high temperatures. -

Heat resistant labels are designed for tracking of PCBs through the entire production cycle. The labels have a permanent adhesive that will resist high heat conditions and stringent conditions associated with soldering, such as flux and cleaning alcohols. They are ideal for thermal transfer labeling in electronics, circuit boards, and aerospace industries.

Heat resistant labels are designed for tracking of PCBs through the entire production cycle. The labels have a permanent adhesive that will resist high heat conditions and stringent conditions associated with soldering, such as flux and cleaning alcohols. They are ideal for thermal transfer labeling in electronics, circuit boards, and aerospace industries. -

Ruilabels designs and manufactures label materials specifically for printed cirduit board harsh environments. Our durable tracking labels maintain the integrity of printed bar codes and images throughout the harshest, multi-cycle PCB manufacturing processes, helping manufacturers accurately control their PCB inventories from production through to customer deliveries.

Ruilabels designs and manufactures label materials specifically for printed cirduit board harsh environments. Our durable tracking labels maintain the integrity of printed bar codes and images throughout the harshest, multi-cycle PCB manufacturing processes, helping manufacturers accurately control their PCB inventories from production through to customer deliveries. -

The label is a constant pressure sensitive acrylic polyimide substrate suitable for printing heat transfer on white surfaces of printed circuit boards used in labels, symbols or related electronic components, specifically designed for logo designs and barcode labels. Ruilabels high temperature resistant label is the ideal material for welding or reforming to maintain perfect performance in a variety of demanding applications in board and SMT.

The label is a constant pressure sensitive acrylic polyimide substrate suitable for printing heat transfer on white surfaces of printed circuit boards used in labels, symbols or related electronic components, specifically designed for logo designs and barcode labels. Ruilabels high temperature resistant label is the ideal material for welding or reforming to maintain perfect performance in a variety of demanding applications in board and SMT. -

Ruilabels supply 6×6mm printed polyimide labels that are specially formulated for high-temperature solutions with excellent heat resistant qualities that do not degrade under harsh conditions. The labels resist peak temperatures of over 300°C, and constant temperatures of 280°C. They are ideal for automotive and aerospace industries, and for electronics identification.

Ruilabels supply 6×6mm printed polyimide labels that are specially formulated for high-temperature solutions with excellent heat resistant qualities that do not degrade under harsh conditions. The labels resist peak temperatures of over 300°C, and constant temperatures of 280°C. They are ideal for automotive and aerospace industries, and for electronics identification. -

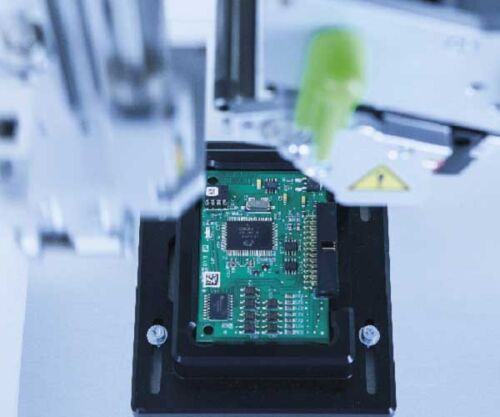

6×6mm QR Labels for tracking and traceability of PCBs in the electronic production processes are very important. It is essential that your PCB is fully tracked from end-to-end so that you can be certain that each one has completed the full manufacture cycle. Our these labels can withstand wave solder environments and multiple harsh washes for printed circuit board and electronic component preprocess labeling.

6×6mm QR Labels for tracking and traceability of PCBs in the electronic production processes are very important. It is essential that your PCB is fully tracked from end-to-end so that you can be certain that each one has completed the full manufacture cycle. Our these labels can withstand wave solder environments and multiple harsh washes for printed circuit board and electronic component preprocess labeling. -

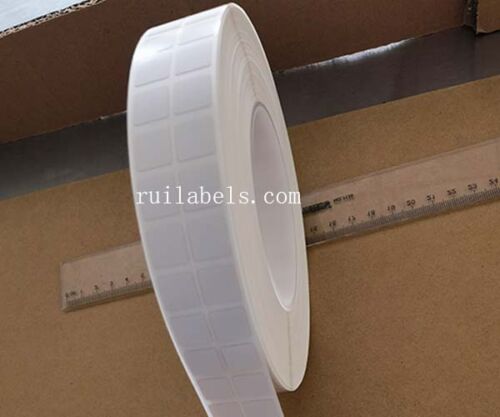

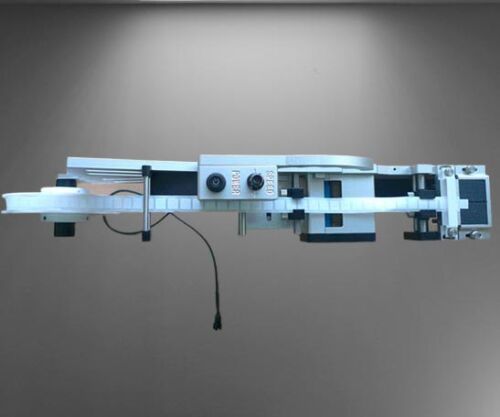

8*8 PCB Labels, this labels are designed to be easily peeled off the liner and presented by a label feeder. The labels are supplied one across on narrow widths so that they can be fitted to a label feeder within the SMT placement machine and simply placed like any other component – fully automating the label placement on the PCB.

8*8 PCB Labels, this labels are designed to be easily peeled off the liner and presented by a label feeder. The labels are supplied one across on narrow widths so that they can be fitted to a label feeder within the SMT placement machine and simply placed like any other component – fully automating the label placement on the PCB. -

Our heat resistant labels are used for identification of high-heat items like circuit boards and related electronic components, where a soldering flux or wave soldering process is used or if the product will be exposed to a chemical cleaning cycle. Backed with a pressure-sensitive acrylic adhesive, these labels have excellent barcode readability after chemical and high-temp exposure.

Our heat resistant labels are used for identification of high-heat items like circuit boards and related electronic components, where a soldering flux or wave soldering process is used or if the product will be exposed to a chemical cleaning cycle. Backed with a pressure-sensitive acrylic adhesive, these labels have excellent barcode readability after chemical and high-temp exposure.